Material Safety Data Sheet of Cryogenic Carbon Dioxide (CO2)

Material Safety Data Sheet of Cryogenic Carbon Dioxide (CO2)

Section 1. Chemical product and company identification

Product name : Carbon Dioxide (Co2)

Supplier : AIRGAS INC., on behalf of its subsidiaries 259

North Radnor-Chester Road Suite 100 Radnor, PA 19087-5283

1-610-687-5253

Product use : Synthetic/Analytical chemistry. CO2 Theatrical Smoke Special Effects

Synonym : Carbonic Acid, Carbon Dioxide Liquid, Carbon Dioxide, Refrigerated

Liquid,

Carbonic Anhydride MSDS # : 001013

Date of : 1/20/2012.

Preparation/Revision

In case of emergency : Call 911 immediately

Section 2. Hazards Identification

Physical state: Gas or Liquid

Emergency overview: WARNING!

GAS:

CONTENTS UNDER PRESURE.

MAY CAUSE RESPIRATORY TRACT, EYE, AND SKIN IRRITATION.

CAN CAUSE TARGET ORGAN DAMAGE.

Do not puncture or incinerate container.

Can cause rapid suffocation.

LIQUID:

MAY CAUSE RESPIRATORY TRACT, EYE, AND SKIN IRRITATION.

CAN CAUSE TARGET ORGAN DAMAGE.

Extremely cold liquid and gas under pressure.

Can cause rapid suffocation.

May cause severe frostbite.

Do not puncture or incinerate container. Avoid contact with eyes,

skin and clothing. May cause target organ damage, based on

animal data.Wash thoroughly after handling. Keep container closed

Avoid breathing gas. Use with adequate ventilation.Contact with

rapidly expanding gas, liquid, or solid can cause frostbite.

Target Organs : May cause damage to the following organs: lungs.

Routes of Entry : Inhalation Dermal Eyes

Potential Acute Health Effects

Eyes : Moderately irritating to eyes. Contact with rapidly expanding gas

may cause burns or frostbite. Contact with cryogenic liquid can

cause frostbite and cryogenic burns.

Skin : Moderately irritating to the skin. Contact with rapidly expanding gas

may cause burns or frostbite. Contact with cryogenic liquid can

cause frostbite and cryogenic burns.

Inhalation : Moderately irritating to the respiratory system.

Ingestion : Ingestion is not a normal route of exposure for gases. Contact with

cryogenic liquid can cause frostbite and cryogenic burns.

Potential Chronic Health Effects

Chronic Effects : May cause target organ damage, based on animal data.

Target Organs : May cause damage to the following organs: lungs.

Medical conditions aggravated

by over exposure : Pre-existing disorders involving any target organs mentioned in this

MSDS as being at- risk may be aggravated by over-exposure to

this product.

See toxicological information (Section 11)

Section 3. Composition, Information on Ingredients

Name: Carbon Dioxide

CAS Number: 124-38-9

%Volume: 100

Exposure Limits:

ACGIH TLV (United States, 2/2010).

STEL: 54000 mg/m3 15 minute(s).

STEL: 30000 ppm 15 minute(s).

TWA: 9000 mg/m3 8 hour(s). TWA: 5000 ppm 8 hour(s).

NIOSH REL (United States, 6/2009).

STEL: 54000 mg/m3 15 minute(s).

STEL: 30000 ppm 15 minute(s).

TWA: 9000 mg/m3 10 hour(s). TWA: 5000 ppm 10 hour(s).

OSHA PEL (United States, 6/2010).

TWA: 9000 mg/m3 8 hour(s).

TWA: 5000 ppm 8 hour(s).

OSHA PEL 1989 (United States, 3/1989).

STEL: 54000 mg/m3 15 minute(s).

STEL: 30000 ppm 15 minute(s).

TWA: 18000 mg/m3 8 hour(s).

TWA: 10000 ppm 8 hour(s).

Section 4. First aid measures

No action shall be taken involving any personal risk or without suitable training.If it is suspected that fumes are still present, the rescuer should wear an appropriate mask or self-contained breathing apparatus.It may be dangerous to the person providing aid to give mouth-to-mouth resuscitation.

Eye contact : Check for and remove any contact lenses. Immediately flush eyes with plenty of water for at least 15 minutes, occasionally lifting the

upper and lower eyelids. Get medical attention immediately.

Skin contact : In case of contact, immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes

Wash clothing before reuse. Clean shoes thoroughly before reuse. Get medical attention immediately.

Frostbite : Try to warm up the frozen tissues and seek medical attention.

Inhalation : Move exposed person to fresh air. If not breathing, if breathing is irregular or if respiratory arrest occurs, provide artificial respiration or oxygen by trained personnel. Loosen tight clothing such as a collar, tie, belt or waistband. Get medical attention immediately. Ingestion : As this product is a gas, refer to the inhalation section.

Section 5. Fire-Fighting Measures

Flammability of the product : Non-Flammable

Products of combustion : Decomposition products may include the following materials:

carbon dioxide

carbon monoxide

Fire-fighting

media and instructions : Use an extinguishing agent suitable for the surrounding fire. Apply water from a safe distance to cool container and protect surrounding area. If involved in fire, shut off flow immediately if it can be done without risk. Contains gas under pressure. In a fire or if heated, a pressure increase will occur and the container may burst or explode.

Special protective

equipment for fire-fighters : Fire-fighters should wear appropriate protective equipment and self-contained breathing apparatus (SCBA) with a full face-piece operated in positive pressure mode.

Section 6. Accidental release measures

Personal precautions : Immediately contact emergency personnel. Keep unnecessary personnel away. Use suitable protective equipment (section 8).

Shut off gas supply if this can be done safely. Isolate area until gas has dispersed.

Environmental precautions : Avoid dispersal of spilled material and runoff and contact with soil, waterways, drains and sewers.

Methods for cleaning up : Immediately contact emergency personnel. Stop leak if without risk.

Note: see section 1 for emergency contact information and section 13 for waste disposal.

Section 7. Handling and storage

Handling : Wash thoroughly after handling. High pressure gas. Do not puncture or incinerate container. Use equipment rated for cylinder pressure. Close valve after each use and when empty. Keep container closed. Avoid contact with skin and clothing. Use with adequate ventilation. Avoid contact with eyes. Protect cylinders from physical damage; do not drag, roll, slide, or drop. Use a suitable hand truck for cylinder movement. Never allow any unprotected part of the body to touch uninsulated pipes or vessels that contain cryogenic liquids. Prevent entrapment of liquid in closed systems or piping without pressure relief devices. Some materials may become brittle at low temperatures and will easily fracture.

Storage : Cylinders should be stored upright, with valve protection cap in place, and firmly secured to prevent falling or being knocked over. Cylinder temperatures should not exceed 52 °C (125 °F). For additional information concerning storage and handling refer to Compressed Gas Association pamphlets P-1 Safe Handling of Compressed Gases in Containers and P12 Safe Handling of Cryogenic Liquids available from the Compressed Gas Association, Inc.

Section 8. Exposure controls/personal protection

Engineering controls : Use only with adequate ventilation. Use process enclosures, local exhaust ventilation or other engineering controls to keep worker exposure to airborne contaminants below any recommended or statutory limits.

Personal protection

Eyes : Safety eyewear complying with an approved standard should be used when a risk assessment indicates this is necessary to avoid exposure to liquid splashes, mists or dusts. When working with cryogenic liquids, wear a full face shield.

Skin : Personal protective equipment for the body should be selected based on the task being performed and the risks involved and should be approved by a specialist before handling this product.

Respiratory : Use a properly fitted, air-purifying or air-fed respirator complying with an approved standard if a risk assessment indicates this is necessary. Respirator selection must be based on known or anticipated exposure levels, the hazards of the product and the safe working limits of the selected respirator.

The applicable standards are (US) 29 CFR 1910.134 and (Canada) Z94.4-93

Hands : Chemical-resistant, impervious gloves complying with an approved standard should be worn at all times when handling chemical products if a risk assessment indicates this is necessary. Insulated gloves suitable for low temperatures Personal protection in case of a large spill product : Self-contained breathing apparatus (SCBA) should be used to avoid inhalation of the Full chemical-resistant suit and self-contained breathing apparatus should be worn only by trained and authorized persons.

Section 9. Physical and chemical properties

Molecular weight : 44.01 g/mole

Molecular formula : C-O2

Melting/freezing point : Sublimation temperature: -79°C (-110.2 to °F)

Critical temperature : 30.9°C (87.6°F)

Vapor pressure : 830 (psig)

Vapor density : 1.53 (Air = 1) Liquid Density@BP: Solid density = 97.5 lb/ft3

(1562 kg/m3)

Specific Volume (ft 3/lb) : 8.7719

Gas Density (lb/ft 3) : 0.114

Section 10. Stability and reactivity

Stability and reactivity : The product is stable.

Hazardous decomposition

products : Under normal conditions of storage and use, hazardous

decomposition products should not be produced.

Hazardous polymerization : Under normal conditions of storage and use, hazardous

polymerization will not occur.

Section 11. Toxicological Information

IDLH : 40000 ppm

Chronic effects on humans : May cause damage to the following organs: lungs.

Other toxic effects on humans : No specific information is available in our database regarding the

other toxic effects of this material to humans.

Specific effects

Carcinogenic effects : No known significant effects or critical hazards.

Mutagenic effects : No known significant effects or critical hazards.

Reproduction toxicity : No known significant effects or critical hazards.

Section 12. Ecological information

Aquatic ecotoxicity: Not available.

Toxicity of the products of biodegradation : Not available.

Environmental fate : Not available.

Environmental hazards : This product shows a low bioaccumulation potential.

Toxicity to the environment : Not available.

Section 13. Disposal considerations

Product removed from the cylinder must be disposed of in accordance with appropriate Federal, State,

local regulation.Return cylinders with residual product to Airgas, Inc.Do not dispose of locally.

Section 14. Regulatory information

United States

U.S. Federal regulations : TSCA 8(a) IUR: This material is listed or exempted.

United States inventory (TSCA 8b): This material is listed or exempted.

SARA 302/304/311/312 extremely hazardous substances: No

products were found.

SARA 302/304 emergency planning and notification: No

products were found.

SARA 302/304/311/312 hazardous chemicals: Carbon dioxide

SARA 311/312 MSDS distribution - chemical inventory - hazard

identification: Carbon dioxide: Sudden release of pressure,

Immediate (acute) health hazard, Delayed (chronic) health hazard

State regulations : Connecticut Carcinogen Reporting: This material is not listed.

Connecticut Hazardous Material Survey: This material is not listed.

Florida substances: This material is not listed.

Illinois Chemical Safety Act: This material is not listed.

Illinois Toxic Substances Disclosure to Employee Act: This material

is not listed.

Louisiana Reporting : This material is not listed.

Louisiana Spill : This material is not listed.

Massachusetts Spill : This material is not listed.

Massachusetts Substances : This material is listed.

Michigan Critical Material : This material is not listed.

Minnesota Hazardous Substances : This material is not listed.

New Jersey Hazardous Substances : This material is listed.

New Jersey Spill : This material is not listed.

New Jersey Toxic Catastrophe Prevention Act : This material is

not listed.

New York Acutely Hazardous Substances : This material is not

listed.

New York Toxic Chemical Release Reporting : This material is

not listed.

Pennsylvania RTK Hazardous Substances : This material is listed.

Rhode Island Hazardous Substances : This material is not listed.

Canada

WHMIS (Canada) : CEPA Toxic substances: This material is listed.

Canadian ARET: This material is not listed.

Canadian NPRI: This material is not listed.

Alberta Designated Substances: This material is not listed.

Ontario Designated Substances: This material is not listed.

Quebec Designated Substances: This material is not listed.

Class A: Compressed gas.

Section 16. Other information

United States

Label requirements : GAS: CONTENTS UNDER PRESSURE. MAY CAUSE RESPIRATORY TRACT, EYE, AND SKIN IRRITATION. CAN CAUSE TARGET ORGAN

DAMAGE. Do not puncture or incinerate container. Can cause rapid suffocation. LIQUID: MAY CAUSE RESPIRATORY TRACT, EYE, AND SKIN IRRITATION. CAN CAUSE TARGET ORGAN DAMAGE. Extremely cold liquid and gas under pressure. Can cause rapid suffocation. May cause severe frostbite.

Canada

Label requirements : Class A: Compressed gas.

---------------------

Carbon dioxide (CO2) is commonly used in the entertainment industry for creating special effects like fog, smoke, and haze. These effects are used to enhance the visual experience of live events, concerts, movies, and TV shows. However, handling CO2 in its cryogenic state requires special precautions to ensure the safety of the performers, technicians, and the audience. This is where the Material Safety Data Sheet (MSDS) comes in, providing information on the potential hazards, safe handling, and storage of cryogenic CO2.

A custom CO2 effects system design is a popular solution for creating dramatic special effects that enhance live performances, concerts, and shows. The system involves the use of liquid CO2 that is pumped through a series of hoses and nozzles to create a range of effects such as fog, smoke, and haze. To ensure the safe and efficient operation of the custom CO2 effects system, it is necessary to have a thorough understanding of the properties and hazards of cryogenic CO2.

When installing a custom CO2 effects system, it is important to consult with experts who have experience in handling cryogenic gases. This includes consulting with engineers, technicians, and manufacturers who have a thorough understanding of the properties and hazards of CO2. They can provide advice on the safe handling and storage of CO2, as well as guidance on the best equipment and materials to use in the system.

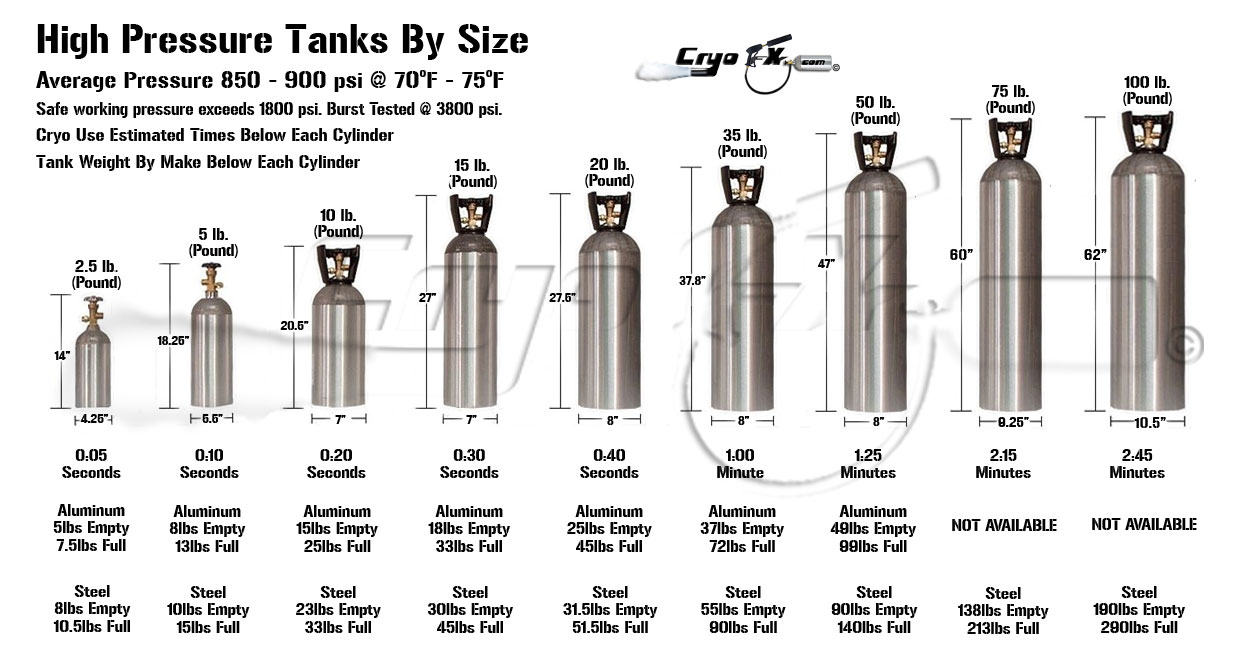

In addition to consulting with experts, it is also essential to have a detailed plan for the installation of the CO2 effects system. This includes a thorough assessment of the space and equipment needed to safely operate the system, as well as a detailed plan for the installation of the CO2 tanks, hoses, and nozzles. A professional CO2 effects system installation can ensure that the system is set up correctly, and that it is safe and efficient to use.

Custom CO2 effects equipment is often used to create unique and memorable special effects for live events and shows. This equipment can include custom-built CO2 tanks, hoses, nozzles, and other components that are tailored to the specific needs of the production. When designing custom CO2 effects equipment, it is important to take into account the properties and hazards of cryogenic CO2, as well as the unique requirements of the production.

CO2 effects system fabrication is an essential part of creating custom CO2 effects equipment. This involves the construction of tanks, hoses, and nozzles that are designed to safely handle cryogenic CO2. To ensure the highest level of safety and efficiency, it is important to use high-quality materials and follow best practices for fabrication and testing.

Smirnoff chimney modification is a popular customization for CO2 effects systems that use a custom-built Smirnoff chimney. The modification involves the addition of a CO2 tank and a series of hoses and nozzles that allow for the creation of dramatic fog effects. To ensure the safe and effective use of the modified Smirnoff chimney, it is important to consult with experts in the field of cryogenic gases.

CO2 effects system upgrades can improve the safety and performance of existing CO2 effects systems. This can include the replacement of outdated equipment, the addition of new safety features, and the use of new materials that are better suited to the properties of cryogenic CO2. By upgrading their CO2 effects systems, production companies can ensure that their shows and events are safe, efficient, and visually stunning.

CO2 effects system consultation is a valuable service that can help production companies to better understand the properties and hazards of cryogenic CO2. By consulting with experts in the field, companies can receive guidance on the safe handling and storage of CO2, as well as advice on the best equipment and materials to use in their CO2 effects systems.