Showven cFlamer Boom Flame Machine

In stock

Description / Showven cFlamer Boom Flame Machine

Showven cFlamer Boom Flame Machine

The Showven cFlamer Boom is an all-in-one special effects powerhouse combining flame balls, spark effects, and a dramatic boom sound—all from one compact, rugged unit. Whether you're producing a concert, live show, or immersive event, this 3-in-1 effect system delivers a high-impact visual and auditory punch without the need for pyrotechnics.

Compatible with ISOPAR, ISOPROPANOL, and color fluid additives, the cFlamer Boom can launch flames up to 33 feet high in brilliant red, green, blue, yellow, or purple. Its rainproof design, advanced safety features, and professional-grade control interfaces make it ideal for both indoor and outdoor productions.

Elevate your events with the Showven cFlamer Boom, a revolutionary 600W fluid-based color flame machine that combines flame balls, sparks, and a dramatic booming sound for an unforgettable multi-sensory experience. Perfect for concerts, festivals, theatrical productions, and large-scale events, this versatile unit delivers vibrant flame balls in red, green, blue, yellow, and purple using Showven’s FX color additives (sold separately), with adjustable flame heights ranging from 26.24 to 32.80 feet for stunning vertical effects. Compatible with ISOPAR, ISOPROPANOL, and HC8200 large (200-gram) sparks consumables, the cFlamer Boom creates dynamic, crackling visuals and auditory impact. Its IP65-rated aluminum and 304 stainless steel housing ensures durability and water resistance, making it ideal for indoor and outdoor use, even in rainy conditions.

Designed for reliability and safety, the cFlamer Boom features a 5.3-liter fuel tank for extended operation, dual high-voltage electron ignitions for reliable flame production, and a fuel filtration system with dual valves to prevent clogs. DMX control with 9-60V signal compatibility allows seamless integration into professional setups, while safety features like an E-stop and ARM indicator light ensure secure operation. Complete with a roadcase for easy transport, the cFlamer Boom is the ultimate solution for creating vibrant, safe, and multi-dimensional flame effects that captivate audiences.

Features and Advantages:

-

Combines flame ball, spark, and boom sound in one unit

-

Shoots flames up to 33 ft high

-

Works with standard fuels (ISOPAR L, ISOPROPANOL)

-

Accepts color fluid additives (FX-RED, GREEN, BLUE, YELLOW, PURPLE)

-

Dual high-voltage electronic igniters for fast ignition

-

Built-in fuel filtration system and dual valve control

-

Uses HC8200 LARGE spark consumables

-

E-stop and ARM indicator light for safety

-

Durable aluminum + stainless steel housing

-

Weather-resistant — safe to use in the rain

-

Controlled via DMX or 9–60V Pyro Signal

-

Pro-grade inputs: NEUTRIK TRUE1, waterproof 3-pin and 5-pin XLR

Features

- Flame balls, sparks, and booming sound effects for a stunning multi-sensory experience.

- Vibrant flame balls in red, green, blue, yellow, and purple with optional Showven FX color additives.

- Adjustable flame height from 26.24 to 32.80 feet for dramatic, high-impact vertical effects.

- IP65-rated aluminum and 304 stainless steel housing for durable, water-resistant performance in all weather conditions.

- Compatible with ISOPAR, ISOPROPANOL, and HC8200 large (200-gram) sparks consumables for versatile effects.

- 5.3-liter fuel tank for extended operation with fewer refills.

- Dual high-voltage electron ignition systems for fast, reliable flame production.

- Fuel filtration system and dual valves for optimal performance and precise flame control.

- DMX control with 9-60V signal compatibility for seamless integration into professional setups.

- E-stop and ARM indicator light for enhanced safety during operation.

- Includes a 1-unit roadcase with handles and casters for easy transport and storage.

- Ideal for concerts, festivals, theatrical productions, and large-scale events requiring dynamic flame effects.

- Includes 9.84FT PowerCON TRUE1 cable for quick, professional setup.

Specifications

General

- Dimensions: 22.83 x 15.74 x 16.85 inches

- Net Weight: 118.80 lbs

- Voltage: AC100-120V, 50/60Hz

- Power Rating: 600W

- Housing Material: Aluminum and 304 Stainless Steel

- Consumable: Isopar L, Isopropanol

- Sparks Consumable: HC8200 Large (200 Gram)

- Color Additives Optional: FX-Red, FX-Green, FX-Blue, FX-Yellow, FX-Purple

- Fuel Tank Capacity: 5.3-Liter

- Maximum Flame Height: 26.24ft to 32.80ft

- Effect Direction: Vertical

- Power Connections: Neutrik PowerCON TRUE1

- Data Connections: IP65-rated 3-Pin and 5-Pin XLR in/out

- Control: DMX, 9-60V signal

- E-Stop: Yes

- ARM Indicator Light: Yes

- Fuel Filtration: Yes

- Ignition: High voltage electron ignition x 2

- Valve: Dual

- Use in Rain: Yes

What’s Included

- (1) cFlamer Boom

- (1) 9.84FT PowerCON TRUE1 Male to Edison Male Power Cable

- (1) 1-Unit Roadcase with Handles and Casters in Black/Silver Finish

Physical

- Shipping Dimensions: 33 x 23 x 25 inches

- Shipping Weight: 250 lbs

Specifications:

| Specification | Details |

|---|---|

| Model | cFlamer Boom |

| Dimensions | 22.8 in (L) × 15.7 in (W) × 16.8 in (H) |

| Shipping Weight | 180 lb |

| Power Supply | AC 100–120V / 200–240V, 50/60 Hz, 600W |

| Housing Material | Aluminum + 304 Stainless Steel |

| Effect Direction | Vertical |

| Max Flame Height | Up to 33 ft |

| Fuel Types | ISOPAR L, ISOPROPANOL, Color Fluid |

| Spark Consumable | HC8200 LARGE |

| Color Additives | FX-RED, GREEN, BLUE, YELLOW, PURPLE |

| Tank Capacity | 1.4 gallons (5.3 L) |

| Control | DMX, 9–60V Pyro Signal |

| Connections | NEUTRIK TRUE1, Waterproof 3-pin and 5-pin XLR IN/OUT |

| Safety Features | Emergency Stop, ARM Light, Rainproof Design, Dual Valves |

| Ignition System | Dual High-Voltage Electronic Ignition |

USER MANUAL

cFlamer Boom

SHOWVEN Technologies Co., Ltd.

Thanks for choosing SHOWVEN cFlamer Boom, we wish it will bring you lots of exciting moments.

Please read the following user’s manual and related product installation guide carefully before

operating this device.

Δ Safety Instructions

1. Safety icons explanation

Safety instructions warn of hazards when handling equipment and provide information on how to avoid

those hazards. They are classified according to the severity of the hazard and are divided into the

following groups. Please do follow all safety instructions in this document!

DANGER: Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

(This signal word is limited to the most extreme situations)

WARNING: Indicates a hazardous situation that, if not avoided, could result in serious injury

CAUTION: Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury.

NOTICE: Provide additional or supplementary information.

2. General Safety Instructions

\ Unauthorized repair are prohibited, it may cause serious incident.

\ Make sure power supply in consistent with the rated voltage of the equipment, and the socket must

well grounded. Unplug and turn off the machine when not use.

\ Please connect DMX cable before power on cFlamer, and ensure that the communication command is

disarmed, and the safety switch of device is under test mode.

\ After turning on the device, no person allows to stay in the safety isolation zone. Ensure all persons

that are part of the show be informed about the safety distance, risks and functions of the device.

\ Always have a CO2 fire extinguisher and an extinguishing blanket in case of needed.

\ If there be any doubt as to the safety operation of the device in any circumstances, the device should

be taken out of service immediately. Be sure the device is in good operating condition before use. If fail

to fire correctly, immediately shut down and check it accordingly. Any questions please always contact

SHOWVEN ([email protected]) for help.

\ Be sure to use high quality fuels, otherwise, it is easily leads to failure or danger. Please keep fuels away

from heat source, sparks, fire or other possibility of ignition. Do not smoke!

\ The operator responsible for the control of flame system must always have a clear view of the device,

so that he/she can stop the show immediately when there is danger. The main AC power switch should

near operator. So that operator can turn off the power of all devices in case of abnormal.

\ Please connect device with SHOWVEN E-STOPPER so that operator can stop the device immediately if

there is any emergency case.

\ The device shall not be altered and applied to other use purpose.

3. Disclaimers:

SHOWVEN technologies Co., Ltd excludes liability for unsafe situations, accidents and damages resulting

from:

1. Ignoring warnings or regulations as shown on product manual or this manual.

2. Use for other applications or circumstances other than those indicated herein.

3. Changes to the device, including use of non-original spare parts, lack of maintenance etc.

4. Dismantling device without authorization from SHOWVEN.

5. Use this machine by unqualified or untrained personnel.

6. Improper use of machine.

WARNING:

A dry powder fire extinguisher, a carbon dioxide fire extinguisher and a fire blanket must be equipped

next to the equipment. Someone must be on duty during operation. In case of fire accident, dry powder

fire extinguisher can be used when the fire is large, and a carbon dioxide fire extinguisher can be used

when the fire is small.

Δ Technical Specifications

\ Model: cFlamer Boom(FA06)

\ Housing Material: Stainless steel + Aluminum

\ Dimension: 580 400 428mm

\ Weight: 54kg

\ Input: AC100-120V / AC 200-240V, 50/60Hz

\ Work Power: 600W

\ Ignition: Dual, high voltage electron ignition

\ Ignition nozzle type: cM

\ Control: DMX , 9-60V pyro signal, Wireless with Wireless DMX Receiver (5-PIN DMX IN with DC5V

power supply)

\ DMX: 3-pin and 5-pin DMX IN / OUT

\ E-Stop Interface: Yes, can be connected in series

\ Effect Direction: Vertical

\ Effect Height:(sparks): 12m (no wind)

\ Effect Height:(flame ball): 10m (no wind)

\ Fuel: SHOWVEN color fluid, ISOPAR L, ISOPROPANOL

\ Color Optional: Red, Green, Blue, Yellow, Purple (only compatible with SHOWVEN original color fluid)

\ Fuel Tank Capacity: 5.3L

\ Fuel Consumption Rate: 200ml / shot

\ Sparks Consumable: SHOWVEN HC8200 LARGE

\ MAX. Sparks Consumable Hopper capacity: 800g

\ HC8200 Consumption Rate: 25g / sparks shot

\ Air Tank Volume: 8L

\ Air Tank Pressure Rebuilt Time: 3min

\ Fuel Tube Filter: Yes

\ Tip Sensor: Yes

\ Usage in Rain: Yes

\ ARM Light: Yes

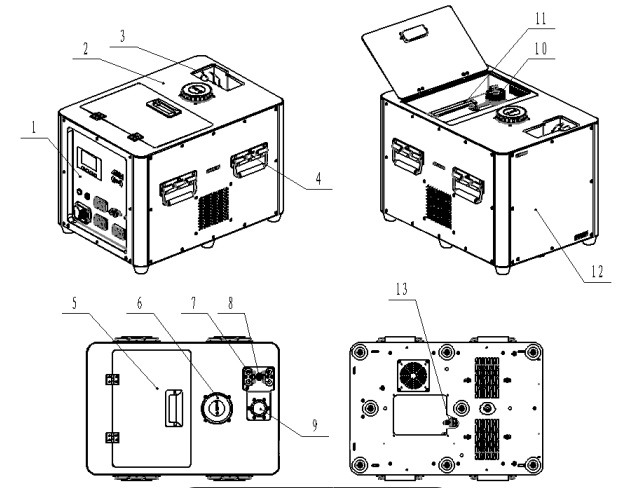

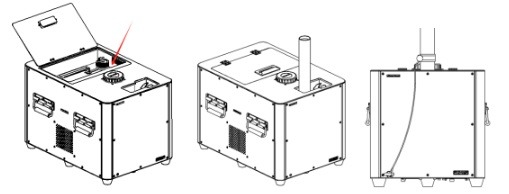

Δ Structure

1. Rear panel

2. Top panel

3. Fire box

4. Handle

5. Fuel tank cover (fuel)

6. Consumable hopper lid (sparks consumable)

7. Igniter

8. Nozzle

9. Output tube

10. Fuel tank cap

11. Fuel tank

12. Front panel

13. External air compressor port (on bottom panel)

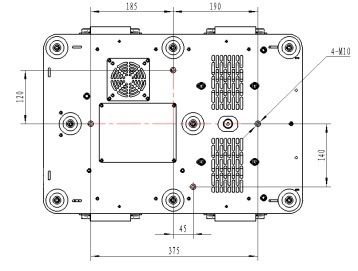

Diagram of bottom panel

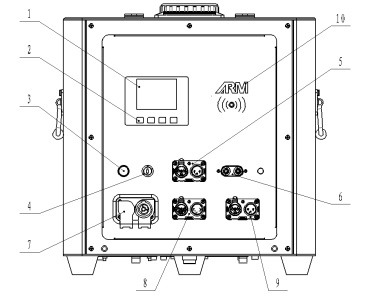

Δ Rear Panel

1. LCD screen

2. Touch button

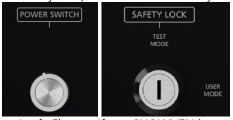

3. Power Switch

4. Safety switch

5. 3-pin XLR IN/OUT

6. 9-60V pyro signal port

7. Power IN / OUT

8. 5-pin XLR IN/OUT (5-PIN XLR IN can charge for wireless DMX pen through pin1 and 4, pin4 with

DC5V power supply)

9. E-stop interface

10. ARM indicator light and RFID card area

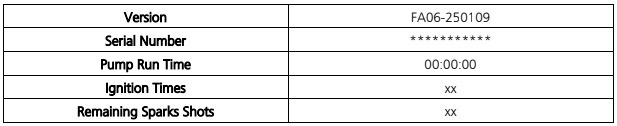

Δ Display and setting

1. Welcome interface

2. Main interface

1.) Status Bar

![]() : appears when “External Trigger” is “ON”

: appears when “External Trigger” is “ON”

![]() : appears when “safety switch” stay at “USER MODE”

: appears when “safety switch” stay at “USER MODE”

6N: DMX channel mode

2.) Data Bar

DMX: DMX address, Background turns from BLACK to RED when DMX cable was connected.

SAFE: Safety address, Background turns from BLACK to RED when DMX cable was connected and

safety channel activated.

PRES1: Pressure value. Background turns from BLACK to RED when pressure reached / exceed 90% of

“set pressure”value.

PRES2: Pressure of air tank. Background turns from BLACK to RED when pressure reached / exceed

90% of “Compression pressure”value.

3.) Message Bar

USER MODE / error or alert information display, Background color turns to RED when under “USER

MODE”.

4.) Touch Button function display:

First Button: MENU / BACK

Second Button: UP / LEFT

Third Button: DOWN / RIGHT

Fourth Button: MONI / EDIT / SAVE

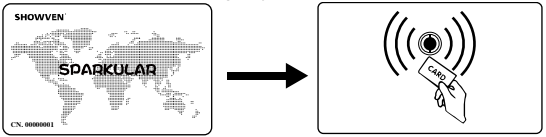

3. RFID area

RFID card come with consumable HC8200 bags, swiping card to identify parameters and types of

granules. The RFID card is disposable, one card can only use one time. Each card of 200g Sparks

Consumable can increase single machine 20 sparks shots, the maximum recharge sparks shots for the

machine is 80.

4. ARM indicator light

Operators can enable/disable the arm indicator light by set the “ARM STATE” in ADVANCED menu. If

“ARM STATE” is ON, there will be three status:

OFF: DMX signal input

BLINK: DMX armed or Ext Ignite in advanced menu is ON

ON: no DMX signal and Ext Ignite in advanced menu is OFF

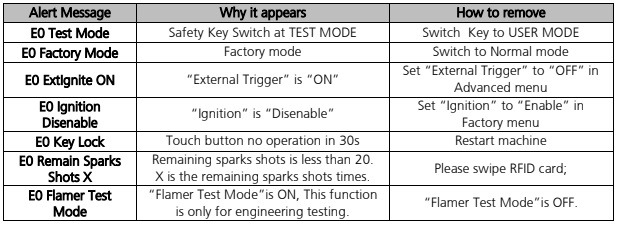

5. Alert Message

6. Error Message

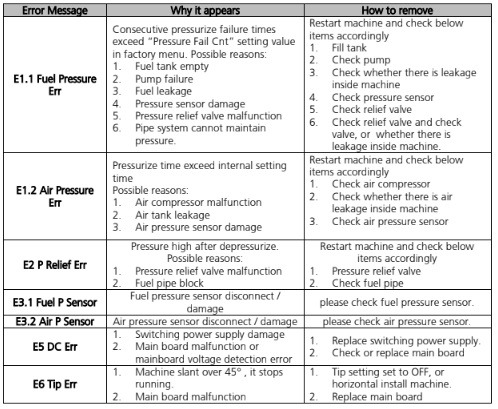

7. Monitoring Interface

Press “MONI” enter below interface

8. Menu Interface

Press “MENU” enter below interface

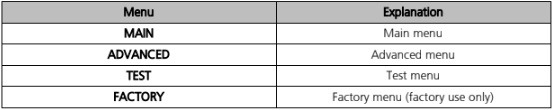

9. Main menu

Select “MAIN” in menu interface, press “EDIT” enter main menu. Use UP / DOWN / SAVE to change the

parameters.

![]()

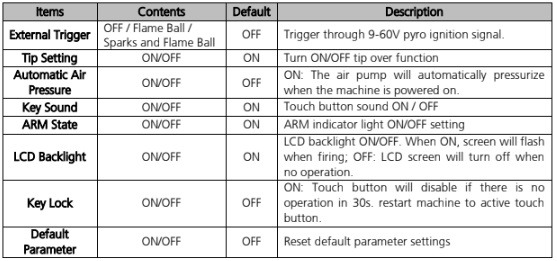

10. Advanced menu

Select “ADVANCED” in menu interface, press “EDIT” enter advanced menu. Use UP / DOWN / SAVE to

change the parameters.

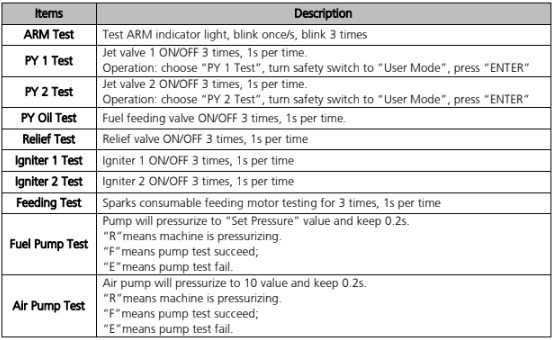

11. Test menu

Please disconnect DMX connection before enter test menu.

Select “TEST” in menu interface, press “EDIT” enter test menu. Use UP / DOWN / SAVE to change the

parameters.

“External Trigger” will disable after enter TEST menu, Pressure relief valve will open, below related items

will shows “Running” when testing, shows “Finish” after test finished

.

.

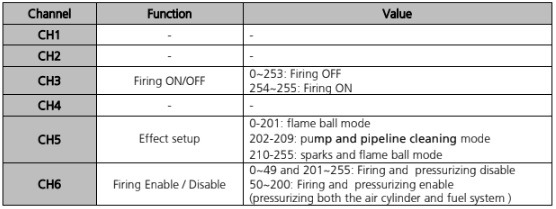

Δ DMX CONTROL

cFlamer Boom occupy 6 channels, channel information as below.

WARNING:

The right sequence of channel settings is as follows: CH5, CH6, and CH3;

When CH5 is set 210-255, the machine will execute the sparks consumable feeding program, so the

sparks effect can not be canceled;

NOTICE:

The time of pressurizing the air cylinder:

(1) flame ball mode: 3min;

(2) pump and pipeline cleaning mode: 1min;

(3) sparks and flame ball mode: 3min;

NOTICE:

When using the SHOWVEN host controller or the FXcommander to control the machine, the controller

can display the pressure value. Specifically, when CH6 is disable, it will show the air pressure. Conversely,

when CH6 is enable, it will display the fuel pressure.

Δ Operation

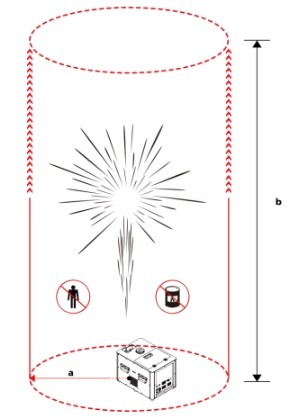

1. Safety distance explanation

Safety distance for cFlamer Boom divided into two parts safety radius around machine (a) and safety

distance at firing direction (b). No person and flammable materials are allowed to stay inside the safety

isolation zone when flamer was armed.

The safety radius around machine with a radius of 3m.

For safety distance at firing direction equals to maximum firing height * 1.5.

![]()

The cFlamer Boom safety isolation zone (show as below) is a cylindrical three-dimensional space with

Safety radius around machine (a) and Height of b. Unauthorized persons and objects are strictly

prohibited from entering.

For angled installation, the safety distance both around machine and firing direction should shift

accordingly.

Safety distance in windy environment

The safety isolation zone radius (a) increase with wind direction and wind speed (v, m/s). The safety

distance in windy conditions can be calculated as below: a = 6 + v;

For example when the wind speed is 3m/s, then the safety isolation zone radius should be 9m, When the

wind speed ≥ 8m/s (wind force ≥ 5), please use it with caution. When wind speed ≥ 17m/s wind force

≥ 8 , please stop use the machine.

2. Install cFlamer

a) Horizontal installation is preferred for the machine.

b) For truss installations always connect with safety rope to ensure extra safety. If there is any other

national or regional guidelines please follow it accordingly.

c) Double confirm the machine was firmly installed.

WARNING:

Ensure the installation position of cFlamer Boom meet above safe distance requirements. cFlamer

Boom supplied with a nozzle cM which generate up to 10m flame ball and 12m sparks.

3. Color fluid preparation

a) Ensure all containers, fuel tanks etc are clean and free of impurities. Highly recommanded to use

container/fuel tank with a fixed color, not mix with different colors. If you have no extra tanks,

please wash container / fuel tank with clean water thoroughly before use another color fluid.

b) When wash the fuel tank, add half of the fuel tank capacity of clean water, shake it repeatedly for

30 seconds, pour out the water, and repeat the cleaning process twice.

c) Perform the mixing operation according to the instructions on the color additive label. For blue,

pay special attention to the proportion and addition order. Add 2 bottles (125ml*2) of BLUE A

liquid to 5L diluent liquid and shake well, and then add 15ml BLUE B liquid. For other colors, just

add 125ml color additive to 5L diluent liquid and shake well.

d) There will be solid precipitate at the bottom of color additive bottle when environment

temperature is low, please shake repeatedly to dissolve the solid precipitate before add it to the

methanol.

e) Please shake and mix the color fluid well before use.

f) The prepared color fluid needs to be stored with a cap and implemented in accordance with the

requirements of the diluent liquid MSDS or local regulations.

NOTICE:

Ensure that the purity of diluent liquid.

WARNING:

The preparation operation should be carried out in a well-ventilated place, away from fire, sparks

and heat sources. Dry powder or carbon dioxide fire extinguishers should be prepared for use in the

operation site.

WARNING:

cFlamer series product compatible with color fluid only prepared with SHOWVEN original color

additives, other colored fuels are forbidden to use on the product, It will sure damage the machine.

4. Install the output tube

a) Open the fuel tank cover and take out output tube of cFlamer Boom, screw it tight to the machine.

b) Install a safety rope to the output tube as below.

5. Fill the cFlamer Boom

c) Switch safety lock to TEST MODE.

d) Fill the fuel tank with qualified color fluid we prepared.

e) To avoid color mix, it is highly recommended to fix the color used on each unit of cFlamer Boom.

In case need to change to another color fluid please execute pipeline clean process (refer to 13.

Pump and pipeline cleaning of this manual).

WARNING:

The warranty is void if any other type of color liquid or additive is used.

NOTICE:

SHOWVEN excludes liability for the losses, damages and accidents caused by not using qualified fuels

in accordance with this requirement.

6. Fill the sparks powder HC8200 and swipe RFID card

Please refill the powder hopper with SHOWVEN original HC8200 LARGE.

a) Swipe an RFID card. Read the card as show below. The screen of the machine flash once if read

successfully. The machine only compatible with V2.0 RFID card from SHOWVEN.

b) The machine will report E0 when Remaining sparks shots is less than 20.

c) Please note each RFID card come with 200g package HC8200 can increase single machine 20

sparks shots, and the maximum recharge shots each time for the machine is 80.

NOTICE:

Make sure to fill the HC8200 LARGE to the consumable hopper, not to the output tube.

WARNING:

The max. sparks consumable hopper capacity is 800g, please do not add excessive consumables.

WARNING:

For safety use only SHOWVEN original HC8200 LARGE, the warranty is void if any other type of

consumable is used.

E-Stopper / E-stop terminator Connection

E-stop interface is a power cut-off interface, the machine can be powered on normally only when E-

STOP in is connected. For safer use of cFlamer Boomwe suggest to connect it with E-stopper. For

operators who don’t want to use E-stopper can plug a E-stop terminator in E-STOP IN to enable the

device.

E-Stopper (optional) connect with single unit of cFlamer Boom.

E-Stopper (optional) connect with multi units of cFlamer Boomin daisy chain.

NOTICE: A unit of E-Stopper can control maximum 24 units of device.

Use E-stop terminator (standard configuration): if without E-Stopper. Plug the E-stop terminator to the

E-STOP IN port to enable the cFlamer.

7. Connecting cFlamer

Make sure the DMX or pyro controller is disarmed or powered off during cable connection.

If control by DMX controller, follow below steps:

a) Connect a DMX cable to the DMX IN socket of first unit of cFlamer Boom, another head of this

DMX cable connect to DMX console (such as FXcommander). Make sure the DMX console is

powered off.

b) Connect a DMX cable to the DMX OUT socket of previous cFlamer, and the other end to the DMX

IN of next machine. Connect all devices in series in this way.

c) Suggest to plug in a DMX terminator into the DMX OUT in last unit of machine to improve signal

reliability. For distance >200m please use SHOWVEN DMX splitter 8 to amplify the signal.

d) Connect a power cable to the POWER IN socket of cFlamer. Make sure power supply in consistent

with the rated voltage of the equipment, and the socket must well grounded.

e) Power on all cFlamer. Check the safety lock, double confirm it stays at “TEST MODE”.

f) Assign DMX address for each unit of cFlamer Boom. If use SHOWVEN host controller or

FXcommander to control the machine please allocate a unique DMX address for each unit of

machine.

If control by 9-60V pyro signal, follow below steps:

a) Connect a power cable to the POWER IN socket of cFlamer. Connect the other end of power cable

to the power source. Make sure power supply in consistent with the rated voltage of the

equipment, and the socket must well grounded.

b) Connect the power control cables to the 9-60V pyro signal connector on cFlamer Boom.

c) Connect the other end of power control cables to the pyro controller (9-60V external trigger

source), such as SHOWVEN PyroSlave series module. Before connect please make sure there is no

pyro signal input.

d) Power on all cFlamer

e) Set the Ext Ignite to ON status in advanced interface, set the firing effect.

NOTICE:

The ventilation fan will on after cFlamer Boom connect with power cable, no matter machine was

power on or not.

8. Power ON the DMX console / Pyro controller and programming

Power on DMX console and program the cFlamer Boomeffect on DMX console or Pyro controller.

9. Test the ignition function of cFlamer Boom

Test the ignition function of cFlamer Boom, we can check whether the igniters of each unit of cFlamer

Boom is working fine. Due to the safety switch is stay at TEST MODE there will be only ignition while

jet solenoid valve is not open, so no flames generated.

10.Firing

a) Double confirm the prescribed safety isolation zone is clear, no person, animal or other property

within this region.

b) Switch the safety lock of cFlamer Boom to USER MODE.

c) Firing, the operator should always have a clear view of the device, so that he/she can stop the

show immediately when there is danger.

NOTICE:

Due to the pump and pipeline cleaning procedure after each show, there will be some water

remains in the pipeline, so the first several shots may spray water and fail ignition. Even though

please make sure no person, animals or other flammable articles stays in the safety isolation area

when firing.

11.Depressurize and Power OFF

a) Depressurize the unit after show or not use the machine for a period of time

b) Power OFF DMX console

c) Press E-Stopper to power OFF all machine (if connect with E-stopper)

d) Switch safety lock of cFlamer Boom to TEST MODE

e) Power OFF each unit of machine

f) Unplug power cable, DMX cable, E-Stopper connection cable etc.

12.Pump and pipeline cleaning

a) Collect all cFlamer Boom, take the color fluid tank out and replace with water tank with no less

than 3L purified water inside.

b) Connect with power and DMX cables, power on machine.

c) Pressurize and depressurize cFlamer Boom 3 times.

d) Pressurize machine and firing 3 times of the pump and pipeline cleaning mode.

e) Pressurize and depressurize cFlamer Boom 3 times again.

f) Emtpy the remaining water in fuel tank

DANGER:

Make sure there is no fuel inside fuel tank when make cleaning procedure, otherwise it may cause

fire.

WARNING:

Pump and pipeline cleaning procedure is a mandatory operation after the machine is used, Not to

do so will shorten the service life of machine due to the corrosive of color fluid and the

accumulation of the sparks consumable.

WARNING:

Before clean test, make sure there are sufficient purified water in the fuel tank. During the

cleaning process, the flamethrower will spray a large amount of water, please ensure there is no

non-waterproof objects or equipment around.

NOTICE:

Pump and pipeline cleaning procedure is also a necessory operation when use a different color on

cFlamer series product, Not to do so will cause abnormal flame color due to the remaining fluid

from previous firing.

13.Clean and package machine

a) Clean the water on machine, wait until it dry

b) Package the machine after it is cool down

Δ Nozzle Replacement and Igniter Position Adjustment

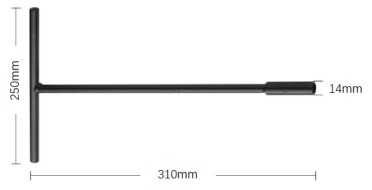

1. Nozzle Replacement

Use 14mm outer hexagon socket wrench (SFMET944) to disassemble the nozzle, clean the nozzle

and nozzle socket with air gun (air compressor), change a new nozzle and install it.

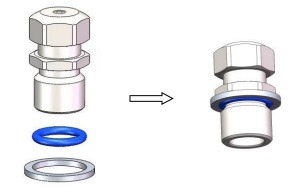

2. Nozzle structure and assemble

Please assemble the stainless steel gasket, O-ring and nozzle as shown below. The O-ring should be

inside the stainless steel gasket, otherwise it may cause fuel leakage from the nozzle.

Please use the nozzle replacement tool hexagon socket wrench to tighten the nozzle.

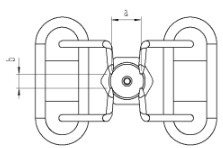

3. Igniter Position Adjustment

Whenever changed the nozzle or ignition is not good, please check igniter pole position according to

below parameters. The right position for each pair of pole should have a gap from tip to tip of 2.5-3mm

(b) and a gap between two igniter of 18 (a). Check the ignition success rate after adjustment by firing.

WARNING: Do unplug the power cable and power off the machine when service flamer.

Δ Maintenance

1. Execute pump and pipeline cleaning procedure every time after use the machine to clean the pump

and pipeline of machine.

2. To maintain the machine in good performance and running status, it is recommended to running the

device at least once per month.

3. Check the ignition probes both before and after each show, if there is any foreign objects on it please

clean it up.

4. Maintenance of the nozzle: Nozzle needs to be cleaned from time to time, and it is recommended that

once every six months (depending on the environment and frequency of use). In the process of using

the equipment, if the flame shape is seriously deformed or the fuel injection line is significantly

deformed or coarsened, the nozzle should be removed immediately for cleaning. If after clean, there

are still problems please replace new nozzle.

5. Maintenance of the O-ring: If it is found that the O-ring of the nozzle is damaged or ageing when

cleaning the nozzle, the Fluorine rubber O-ring should be replaced in time.

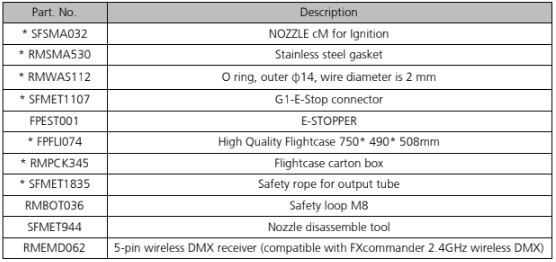

Δ Optional Parts for cFlamer

NOTICE:

The standard accessories are marked with *

Δ Warranty Instructions

\ Sincere thanks for your choosing our products, you will receive quality service from us

\ The product warranty period is one year. If there are any quality problems within 7 days after shipping

out from our factory, we can exchange a brand new same model machine for you

\ We will offer free of charge maintenance service for machines which with hardware malfunction

(except for the instrument damage caused by human factors) in warranty period. Please don't repair

machine without factory permission

Below situations NOT included in warranty service:

\ Damage caused by use unqualified fuels;

\ Damage caused by improper transportation, usage, management, and maintenance, or damage caused

by human factors;

\ Disassemble, modify or repair products without permission;

\ Damage caused by external reasons (lightning strike, power supply etc.)

\ Damage caused by improper installation or use;

For product damage not included in warranty range, we can provide paid service.

Invoice is necessary when applying for maintenance service from SHOWVEN