Showven Circle Flamer X-F1800

In stock

Description / Showven Circle Flamer X-F1800

Showven Circle Flamer X-F1800 DMX Flame Machine is perfect for stages and event looking for a DMX Flame Machine / DMX 512 Pyro Machine.

The Showven Flame Machine, also known as a High Output Showven Pyro Machine has many features for professional stages.

Features and advantages for Showven Circle Flamer X-F1800

- Fluid driven flamer system with 210° swiveling angles;\

- Up to 88 preset firing sequences;

- Nozzle front design, safer for operator;

- Safety lock with switchable test mode;

- Stainless steel nozzle, reliable and durable;

- Double electromagnetic valves design for additional safety;

- Double pump ensure stable pressure;

- Fitted with igniter signal interface, compatible with fireworks firing system;

- Neutrik® powerCON TRUE1 in/out, Neutrik 3-pin & 5-pin DMX in/out;

- Compatible with SHOWVEN original host controller.

Specifications for Sparkular Flame / Pyro Machine:

- Model:Circle Flamer X-F1800

- Dimension:590 x 360 x 370mm

- Input:AC100-240V,50-60Hz

- Work power:380W

- DMX interface:3-pin and 5-pin double DMX socket

- Control:Standard DMX 512, compatible with wireless DMX

- Effect height:Up to 8-10m (no wind)

- Effect angles:210° (±105°)

- Fuel:ISOPAR-G, H, L, M; ISOPROPANEL, BIOETHANOL

- Fuel bottle capacity:10L

- EXT. battery powered: YES

___________________________________________________________________________________

Showven Technologies Co., Ltd.

Δ Foreword

Thanks for choosing SHOWVEN CIRCLE FLAMER X-F1800, we wish it will bring you lots of exciting

moments. Please read the following manual carefully before operating this product. Operate according to

instructions is very important for safety, and can elongate the service life of the machine

Strictly follow the instruction in the manual when operate CIRCLE FLAMER X-F1800. If you have any

doubts, please contact SHOWVEN technologies Co., Ltd by [email protected]

We assume the person who use or come in contact with the device are familiar with how the device

should be handled. This includes proper use, maintenance and repair of the machine as defined in this

user manual.

Δ Warning

\ This product is only suitable for qualified or skilled operators who has experience with the technology

of the device and is particularly informed about the types of fuel used by the device.

\ Unauthorized repair are prohibited, it may cause serious incident

\ Make sure power supply in consistent with the rated voltage of the equipment, and the socket must

well grounded. Unplug and turn off the machine when not use

\ Before connect the power cable, communication DMX cable should well connected and ensure the

command keep at firing OFF status. And safety switch on CIRCLE FLAMER X-F1800 stay at TEST MODE.

\ Before power on the machine, please check carefully the safety distance and make sure it meets the

requirements in this manual.

\ The device can only be placed horizontally.

\ After turning on the device, no person allows to stay in the danger area. Ensure all persons that are

part of the show be informed about the safety distance, risks and functions of the device

\ Always have a CO2 fire extinguisher and an extinguishing blanket in case of needed

\ If there be any doubt as to the safety operation of the device in any circumstances, the device should

be taken out of service immediately. Be sure the device is in good operating condition before use. If fail

to fire correctly, immediately shut down and check it accordingly

\ Be sure to use high quality flame fluid, otherwise, it is easily leads to failure or danger. Be careful when

refill the flame fluid tank. Please keep flame fluid away from heat source, sparks, fire or other possibility

of ignition. Do not smoke!

\ The operator responsible for the control of Circle Flamer must always have a clear view of the device,

so that he/she can stop the show immediately when there is danger. The main AC power switch should

near operator. So that operator can turn off the power of all devices in case of abnormal

\ The device shall not be altered and applied to other use purpose

Δ Disclaimers:

SHOWVEN technologies Co., Ltd excludes liability for unsafe situations, accidents and damages resulting

from:

1. Ignoring warnings or regulations as shown on circle flamer or this manual

2. Use for other applications or circumstances other than those indicated herein

3. Changes to the circle flamer, including use of non-original spare parts

4. Removed safety cover without authorization from SHOWVEN.

5. Use this machine by unqualified or untrained personnel.

6. Improper use of machine.

Δ Functional Characteristics

\ Fluid driven flamer system with 210° swiveling angles

\ Up to 88 preset firing sequences

\ Nozzle front design, safer for operator

\ Safety lock with switchable test mode

\ Stainless steel nozzle, reliable and durable

\ Double electromagnetic valves design for additional safety

\ Double pump ensure stable pressure

\ Fitted with 9-60V pyro signal interface, compatible with fireworks firing system

\ Neutrik® powerCON TRUE1 in/out, Neutrik® 3-pin & 5-pin DMX in/out

\ Compatible with SHOWVEN original host controller

Δ Technical Specifications

\ MODEL: X-F1800

\ DIMENSION: 590× 360× 370mm

\ WEIGHT: 30kg

\ VOLTAGE: AC100-120V or AC200-240V, 50/60Hz

\ POWER: 380W

\ USAGE IN RAIN: YES

\ CONTROL: DMX, 9-60V pyro signal

\ INTERFACE: Neutrik® powerCON TRUE1 IN/OUT

Neutrik® 3-pin& 5-pin XLR IN/OUT

\ FLAME HEIGHT: up to 8-10m (no wind)

\ FIRING ANGLES: 210°(± 105°)

\ FUEL: ISOPAR-G, H, L, M; ISOPROPANEL

\ FUEL TANK CAPACITY: 10L

\ FUEL CONSUMPTION RATE: 60ml/s(M), 30ml/s(L), 15ml/s(EL)

\ EXT. BATTERY POWERED: YES

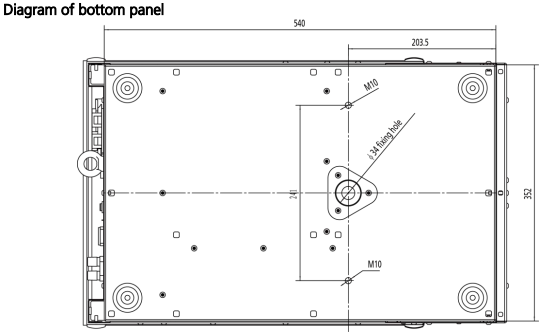

\ Stereo Stand Hole: Yes, ( 36mm depth 88mm)

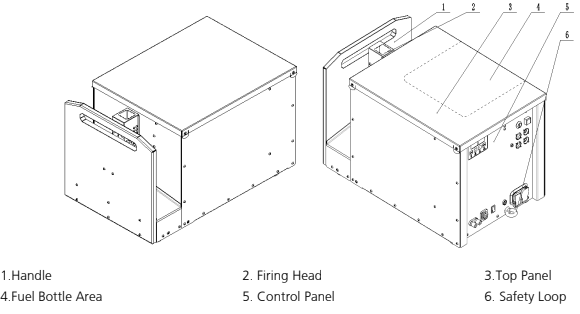

Δ Structure of Circle Flamer

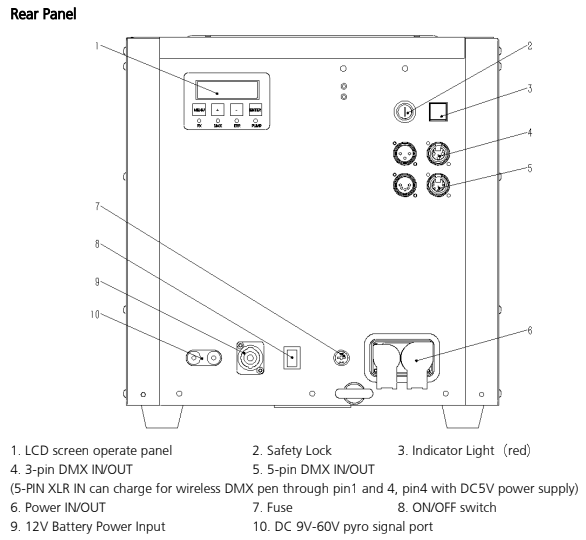

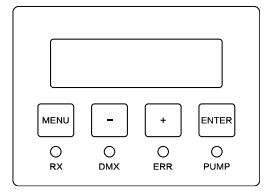

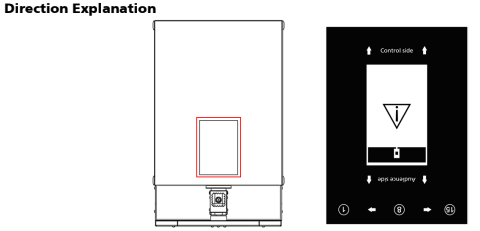

Δ Operation Panel

1. LED Display Area:

RX: Radio receiving (reserved)

DMX: DMX signal. Flash means DMX signal available, otherwise no DMX signal

ERR: Light on when there is an error

PUMP: Light on when pump is running

2. Button Functions:

MENU: Switch interface to setup parameter

+: Parameter Up

-: Parameter Down

ENTER: Confirm and save parameters (screen will flash when parameters saved)

Note: screen display will switch to main interface if not press button in 10s.

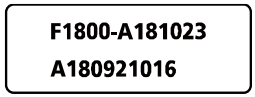

3. Welcome Interface:

First Line: Product model and software version

Second Line: Equipment series number

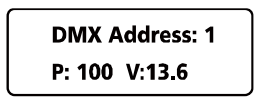

4. Main Interface:

First Line: DMX address

Second Line: “P: 100” means Pressure100 (100=10bar); “V: 13.6” means internal voltage is 13.6V

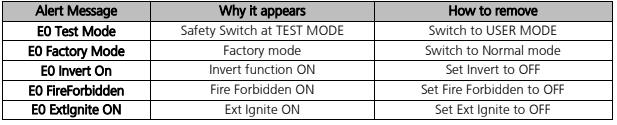

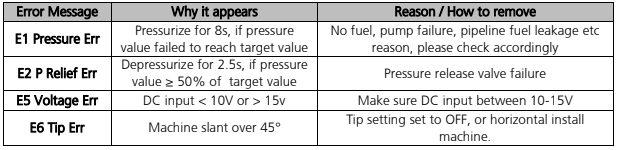

5. Alert Message:

6. Error Message

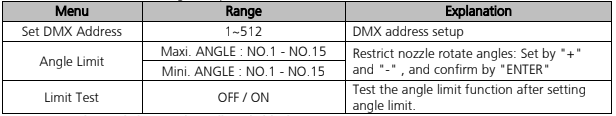

7. Interface setup:

Press “MENU” to switch through setup menu

Steps setting the angle limit and install angle blocks.

a) Set the “Maxi. Angle” and “Mini. Angle”, press “ENTER” to save the changes.

b) Install the angel block plates.

c) Running the Limit Test by set it to ON, and press ENTER, nozzle will move from Mini. Angle to Maxi.

Angle, then to the middle.

d) After confirm the software angle limit control works well, then put angle limit rod at corresponding

Mini. Angle and Maxi. Angle. Running Limit test again to reconfirm the angle limit rod was correctly

installed.

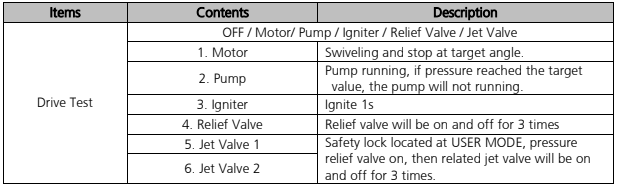

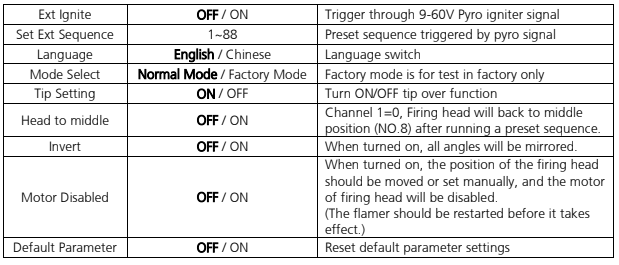

8. Advanced Interface:

Press “MENU” 3s enter advanced interface, press “MENU” to switch interface, press “MENU” 3s can

back to main interface

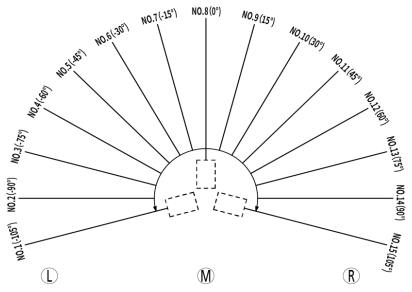

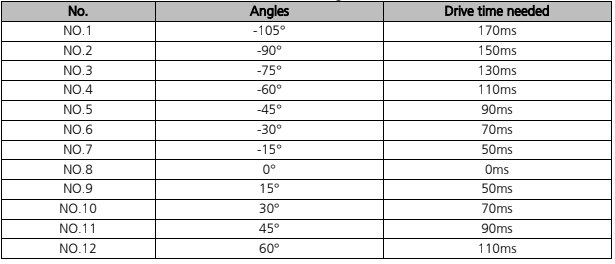

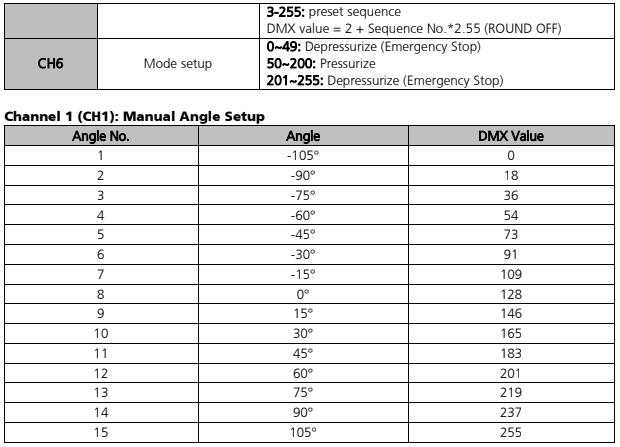

Δ Firing Angles:

The firing angle for CIRCLE FLAMER is ± 105°, from the Audience Side view, there are altogether 15 firing

angles as below.

Δ Drive time for Effects:

Time needed for the motor drive from NO.8 to relevant angle.

For example for the motor drive from 0°to 45°, it need 90ms, when operator design a show to

synchronize to music, this drive time must be calculated.

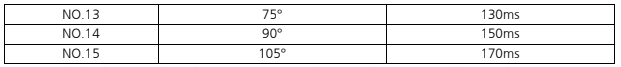

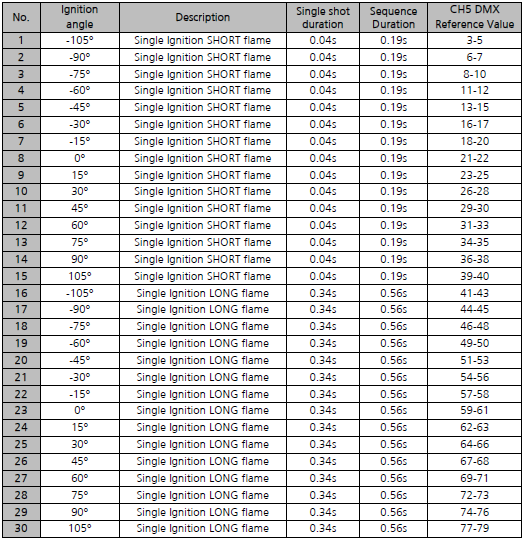

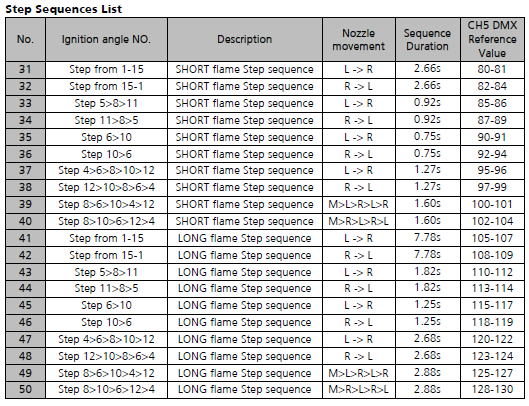

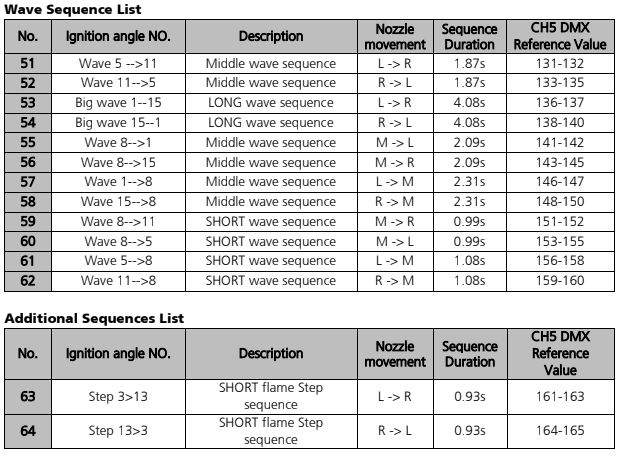

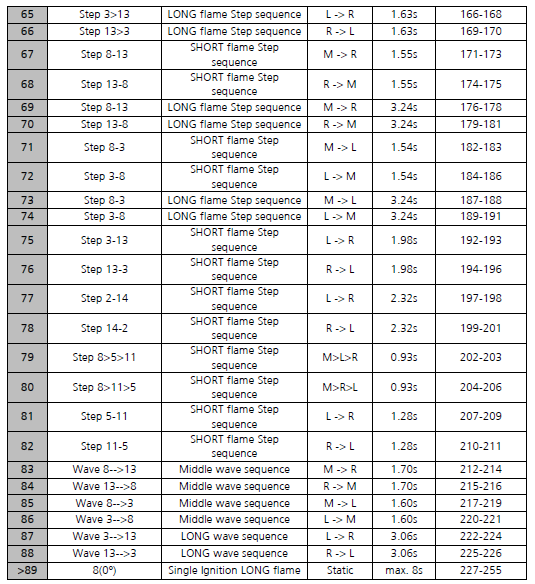

Δ CIRCLE FLAMER X-F1800 Firing Sequences

CIRCLE FLAMER X-F1800 has 88 preset sequences, operator use related channel DMX value or sequence

No. to access certain sequence. Below, you can find sequence list and single ignitions.

Single Ignition Sequence List

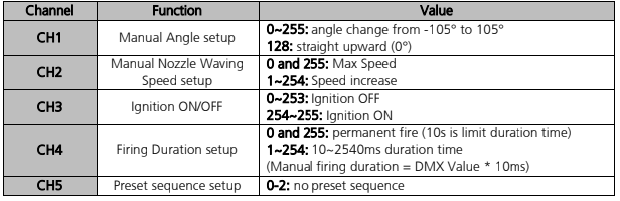

Δ DMX CONTROL

CIRCLE FLAMER X-F1800 occupies 6 channels.

1. The first channel controls the firing angle. It defines to which angle the nozzle of CIRCLE FLAMER move

to. The angle can be chosen anywhere between -105° to +105° (DMX value 0 to 255)

2. The DMX value for angle of 0° is 127.5 (round up 128). Use this value, following formula can be used

to calculate all other angles ∠ in degree. Please always note the prefix of the angle

DMX Value = 127.5 + (∠*1.2145)

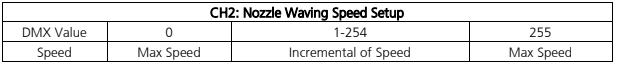

Channel 2 (CH2): Manual Nozzle Waving Speed Setup

The second channel defines the nozzle waving speed. It work together with Channel 1 for manual firing

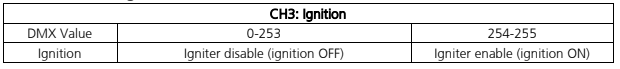

Channel 3 (CH3): Ignition ON/OFF

The third channel activates the actual ignition. If the DMX value of this channel higher than 253, the

CIRCLE FLAMER will ignite.

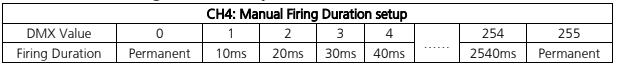

Channel 4 (CH4): Firing Duration setup

The fourth channel is the firing duration setup

Below formula can be used to calculate the firing duration (ms):

DMX Value = t/10

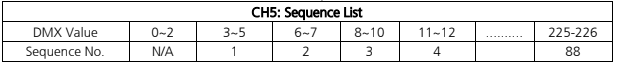

Channel 5 (CH5): Program Sequence setup

The fifth Channel allows to firing a preset sequence. Three DMX values can be used for one of the

programmed firing sequence from above sequence list (refer to above sequence list table).

Below formula can be used to calculate firing sequence:

DMX Value = 2 + Sequence No.*2.55

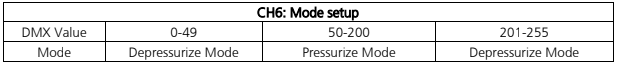

Channel 6 (CH6): Mode setup

The sixth channel is the working mode of pump.

When the safety lock located at TEST MODE, set DMX value between 50-200 to test the system. For

safety, the device will not pressurize.

When the safety lock located at USER MODE, the device pressurize activated by set DMX value between

50-200. The device can generate flames under Pressurize mode.

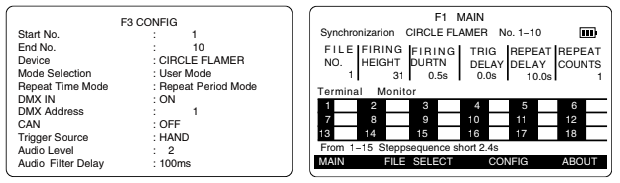

Δ Control with SHOWVEN Host Controller ZK6200/ZK6300

If use SHOWVEN Host Controller ZK6200 or ZK6300 to program the CIRCLE FLAMER X-F3600, please set

on Host Controller. The setting step is:

Press “F3” on Host Controller – find “Device” – choose the right device “CIRCLE FLAMER”.

Host Controller with bi-directional communication with device, please allocate a unique DMX address for

each unit of CIRCLE FLAMER X-F3600.

Press “Pre-heat” to start to pressurize CIRCLE FLAMER X-F3600.

Firing the preset flame effect by enter the preset sequence No. to FIRING HEIGHT.

Δ Operation

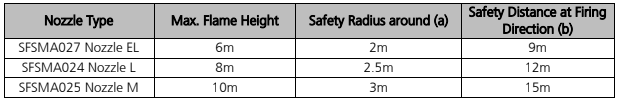

1. Safety Distance

Definition and Instructions

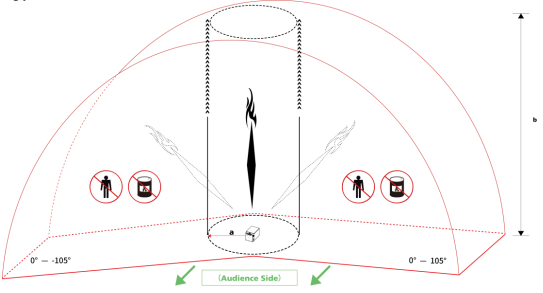

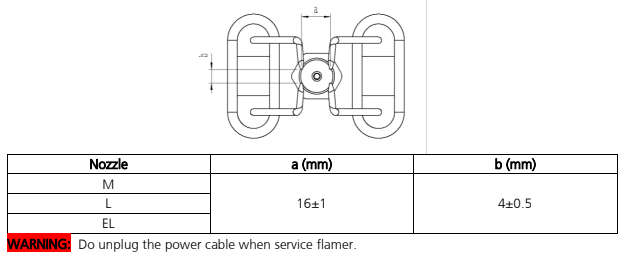

Safety distance for CIRCLE FLAMER X-F1800 divided into two parts safety radius around machine (a) and

safety distance at firing direction (b). No person and flammable materials are allowed to stay inside the

safety isolation zone when flamer was armed.

The safety radius around machine depends on the firing height (nozzle size).

For safety distance at firing direction equals to maximum firing height * 1.5. CIRCLE FLAMER X-F1800

with maximum 105 waving firing angles, when firing step sequence, wave sequence or additional

sequences the safety isolation zone is a three-dimensional sector area.

The CIRCLE FLAMER X-F1800 safety isolation zone is a three-dimensional space with a cross-section of

210° sector enclosed by a and b (check below diagram). We can understand it as a safety area formed by

a safety column with diameter of a, height of b rotate of ± 105 degrees. Unauthorized persons and

objects are strictly prohibited from entering. Depending on the firing sequence / angles the sector area

changes accordingly.

For angled installation, the safety distance both around machine and firing direction should shift

accordingly.

Safety distance in windy environment

The safety isolation zone radius (a) increase with wind direction and wind speed (v, m/s). The safety

distance in windy conditions can be calculated as below:

For Nozzle L: a = 2.5 + v;

For example when the wind speed is 3m/s, we use the Nozzle L, then the safety isolation zone radius

should be 5.5m.

CAUTION:

When the wind speed ≥ 8m/s (wind force ≥ 5), please use it with caution. When wind speed ≥ 17m/s

wind force ≥ 8 , please stop use flamer.

There is direction explanation on top panel of CIRCLE FLAMER X-F1800 as show above picture.

1. 1 to 15 is the firing angle of CIRCLE FLAMER X-F1800, Far Right is position 15, Middle is position 8,

Far Left is position 1.

2. Audience side and control side are indicated in above picture.

Note: in order to indicate correct direction, please place the top panel correctly.

Label of CIRCLE FLAMER X-F1800

The label is at rear panel of machine and information is show as below.

Fuels for CIRCLE FLAMER X-F1800

1. Water content in fuel should less than 0.5%

2. For maximum safety, please use fuel with flash point between 60-80°C, ISOPAR L is highly

recommended.

3. Ethanol is not suggested due to three reasons, first ethanol is highly flammable makes it not as safe as

ISOPAR; secondly the color of flame is very weak; thirdly there are always high water content (> 0.5%)

in ethanol.

4. Colored fuels are forbidden to use on CIRCLE FLAMER X-F1800 it may damage the machine.

SHOWVEN excludes liability for the losses, damages and accidents caused by not using qualified fuels in

accordance with this requirement.

Always have a dry powder fire extinguisher, a CO2 fire extinguisher and an extinguishing blanket next to

the equipment in case of needed. And someone must be on duty during operation. In case accident

occurs, a dry powder fire extinguisher can be used when the fire is large, and a carbon dioxide fire

extinguisher can be used when the fire is small.

2. Install CIRCLE FLAMER X-F1800

a) Choose the correct nozzle, ensure the installation position of CIRCLE FLAMER X-F1800 meet above

safe distance requirements. New CIRCLE FLAMER X-F1800 supplied with a nozzle M which generate

up to 10m flame.

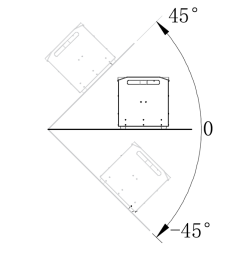

b) Horizontal installation is preferred for CIRCLE FLAMER X-F1800. If need to install CIRCLE FLAMER X-

F1800 in angles, please turn the TIP Setting to OFF status first. X-F1800 with maximum tilt angle of

45° or -45°, and it can be angled to the direction as show in below picture. Besides please be aware

the fuel level in fuel tank to avoid fuel leakage when tilt installation.

c) Make sure CIRCLE FLAMER X-F1800 is securely installed. For truss installations always connect with

safety rope to ensure extra safety. If there is any other national or regional guidelines please follow it

accordingly.

3. Connect Power and DMX cable to CIRCLE FLAMER X-F1800

Before power and/or DMX cable connection, make sure safety lock of CIRCLE FLAMER X-F1800 stay at

TEST MODE as above picture.

If control by DMX, follow below steps:

a) Connect a power cable to the POWER IN socket of CIRCLE FLAMER X-F1800. Connect the other end

of power cable to the power source. Make sure power supply in consistent with the rated voltage of

the equipment, and the socket must well grounded.

b) Each unit of CIRCLE FLAMER X-F1800 can be connected to power supply directly. If connect

machine in sequence, please connect a power link cable to the POWER OUT of previous machine,

connect the other end of the power link cable to POWER IN of the next machine. Do not connect

exceed units to a single electrical circuit.

c) Power on CIRCLE FLAMER X-F1800

d) Assign a DMX address for each unit of machine. If use SHOWVEN host controller or FXcommander

to control the machine please allocate a unique DMX address for each unit of machine.

e) Connect a DMX cable to the DMX IN socket of first unit of X-F1800, another head of this DMX cable

connect to DMX console (such as FXcommander). Make sure the DMX console is powered off.

f) Connect a DMX cable to the DMX OUT socket of previous X-F1800, and the other end to the DMX

IN of next machine. Connect all devices in series in this way.

g) Suggest to plug in a DMX terminator into the DMX OUT in last unit of machine to improve signal

reliability. Signal amplifier is required for long distance (>200m) DMX signal transmission.

If control by 9-60V pyro signal, follow below steps:

a) Connect a power cable to the POWER IN socket of CIRCLE FLAMER X-F1800. Connect the other end

of power cable to the power source. Make sure power supply in consistent with the rated voltage of

the equipment, and the socket must well grounded.

b) Each unit of CIRCLE FLAMER X-F1800 can be connected to power supply directly. If connect

machine in sequence, please connect a power link cable to the POWER OUT of previous machine,

connect the other end of the power link cable to POWER IN of the next machine. Do not connect

exceed units to a single electrical circuit.

c) Connect the power control cables to the 9-60V pyro signal connector on CIRCLE FLAMER X-F1800.

d) Connect the other end of power control cables to the pyro controller (9-60V external trigger source).

Make sure the pyro controller is powered off

e) Power on all CIRCLE FLAMER X-F1800

f) Set the Ext Ignite to ON status in advanced interface, set the firing sequence by choose a sequence

No. at Set Ext Sequence.

4. Power ON the DMX console or pyro controller

5. Programming

Program the CIRCLE FLAMER X-F1800 with DMX console.

6. Test the ignition function of CIRCLE FLAMER X-F1800

Test the ignition function of CIRCLE FLAMER X-F1800, we can check whether the igniters of each unit

of X-F1800 is working fine. Due to the safety switch is stay at TEST MODE the pump won’t work, there

will be only ignition while no fuel spray out, so no flames generated.

7. Fill the CIRCLE FLAMER X-F1800

Please fill the machine with qualified fuel. The fuels suggested on CIRCLE FLAMER are ISOPAR,

ISOPROPANOL, please make sure water content in fuel should less than 0.5%.

8. Firing

a) Double confirm the prescribed safety isolation zone is clear, no person, animal or other property

within this region.

b) Switch the safety switch of CIRCLE FLAMER X-F1800 to USER MODE.

c) Pressurize CIRCLE FLAMER X-F1800.

d) Firing, the operator should always have a clear view of the device, so that he/she can stop the show

immediately when there is danger.

9. Depressurize

Depressurize all CIRCLE FLAMER after use or if not use for a long time during the show we also

suggest to depressurize to ensure the safety.

10. Power OFF

a) Power OFF DMX console

b) Switch safety switch of CIRCLE FLAMER X-F1800 to TEST MODE

c) Power OFF CIRCLE FLAMER X-F1800

d) Unplug power cable, DMX cable.

Δ Nozzles and Nozzle Replacement

Nozzles and Flame Height

Nozzle M: (standard configuration)

Short flame: 5-7m,

Long flame: 8-10m.

Nozzle L:

Short flame: 3-5m,

Long flame: 6-8m.

Nozzle EL:

Short flame: 3-4m,

Long flame: 4-6m.

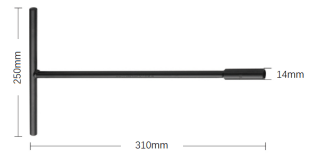

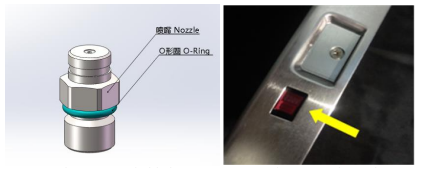

Nozzle Replacement Wrench

Use 14mm outer hexagon socket wrench to disassemble the nozzle, clean the nozzle and nozzle socket

with air gun (air compressor), change a different nozzle and install it.

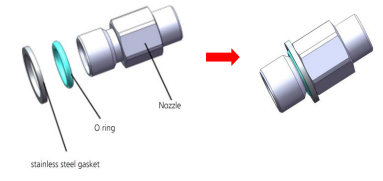

Nozzle Installation available in new design

Please assemble the stailess steel gasket(RMSMA530), O ring and nozzle main part according to below

picture. The O ring should be inside the stailess steel gasket, otherwise it may leads to fuel leakage.

Use nozzle replacement tool outer hexagon socket wrench to tighten the nozzle.

Δ Igniter Position Adjustment

Whenever changed the nozzle or ignition is not good, please check igniter pole position according to

below parameters. Check the ignition success rate after adjustment by firing.

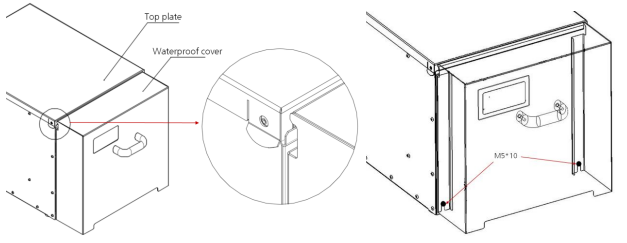

Δ Waterproof cover installation

Hang the waterproof cover on the rear panel side of the top cover and fix it with 2pcs of M5*10 screws

as shown in below picture.

Δ Battery Recommendation

CIRCLE FLAMER can be driven by battery, for use of Battery power supply: CIRCLE FLAMER X-F1800 with

stable internal circuit design, please support X-F1800 with battery voltage higher than 12V. The driving

speed of motor won’t change because of the decrease of battery power supply.

Battery options: 12V lead-acid battery (above 30AH, with more than 24h standby).

For Lithium battery, please use battery with output above 30A. Socket type: NEUTRIK-NL4FX, 4 pin audio

connector (1+ connect 12V anode, 1- connect 12V cathode). Connecting power cables should above

14AWG.

Maintenance

1. To maintain the system in good performance and running status, it is recommended to running the

device at least once per month.

2. Check the ignition probes both before and after each show, if there is any foreign objects on it please

clean it up.

3. Maintenance of the nozzle: Nozzle needs to be cleaned from time to time, and it is recommended that

once every six months (depending on the environment and frequency of use). In the process of using

the equipment, if the flame shape is seriously deformed or the fuel injection line is significantly

deformed or coarsened, the nozzle should be removed immediately for cleaning. If after clean, there

are still problems please replace new nozzle.

4. Maintenance of the O-ring: If it is found that the O-ring of the nozzle is damaged or ageing when

cleaning the nozzle, the O-ring should be replaced in time (material and size of O-ring: fluororubber O-

ring, the outermost diameter is 14 mm, and the line diameter is 2 mm).

5. Switchable power input design, switchable between 110V and 220V as show above picture (voltage

will show on it). The power supply is located on the side of the electric control, and you should remove

the cover before switch it.

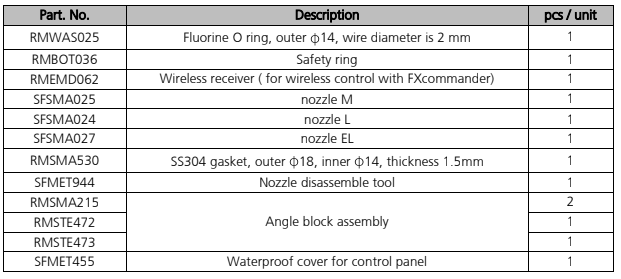

Δ Optional Parts for CIRCLE FLAMER X-F1800

Δ Warranty Instructions

\ Sincere thanks for your choosing our products, you will receive quality service from us

\ The product warranty period is one year. If there are any quality problems within 7 days after shipping

out from our factory, we can exchange a brand new same model machine for you

\ We will offer free of charge maintenance service for machines which with hardware malfunction

(except for the instrument damage caused by human factors) in warranty period. Please don't repair

machine without factory permission

Below situations NOT included in warranty service:

\ Damage caused by use unqualified fuels;

\ Damage caused by improper transportation, usage, management, and maintenance, or

damage caused by human factors;

\ Disassemble, modify or repair products without permission;

\ Damage caused by external reasons (lightning strike, power supply etc.)

\ Damage caused by improper installation or use;

For product damage not included in warranty range, we can provide paid service.

Invoice is necessary when applying for maintenance service from SHOWVEN