Showven Sparkular Wheel

In stock

Description / Showven Sparkular Wheel

The Showven Sparkular WHEEL is a revolutionary rotating spark effect system designed to create breathtaking circular or spiral effects with 360° programmable rotation. Ideal for stage shows, concerts, clubs, and event venues, this unit delivers non-pyro spark effects in a controlled and safe format—making it perfect for indoor use.

With precise DMX and RDM control, the sDarkular WHEEL allows full customization of rotation direction, speed, and spark height. You can also pair it with multiple units for stunning synchronized shows. Built with premium materials and designed to withstand the demands of touring, this system adds dramatic motion and intensity to any production.

Transform your events with the Showven Sparkular Wheel, a revolutionary 360-degree rotating cold spark effect machine that delivers breathtaking, non-hazardous spark displays. Perfect for large stages, special events, and intimate gatherings like weddings, this 500W machine features rotating nozzles that create dynamic molten iron flower effects or simulate fireworks wheels when paired with multiple units. With adjustable rotation speed, direction, and angles, the Sparkular Wheel offers endless creative possibilities, producing spark effects up to 22.96ft in upward, downward, or rotating directions. Its rainproof 304 stainless steel housing ensures reliable performance in any weather, making it ideal for both indoor and outdoor use.

Engineered for safety and precision, the Sparkular Wheel includes an auto dynamic control system with multi-sensor feedback for secure operation and a 320x240mm color LCD screen for real-time monitoring. The 550-gram hopper, with a 50 grams per minute consumption rate, delivers consistent, high-impact effects, while DMX control with 6 channels allows seamless integration into professional setups. Equipped with Neutrik PowerCON TRUE1 and IP65-rated XLR connectors, plus mounting hardware for versatile installation, the Sparkular Wheel combines durability, ease of use, and stunning visuals to elevate any production.

Features and Advantages:

-

Fully programmable 360° rotating spark effect

-

Adjustable rotation direction, speed, and spark height

-

Produces non-pyrotechnic cold spark effects

-

Supports synchronized multiple-unit setups

-

High-performance motorized rotation mechanism

-

RDM & DMX controllable for complete show integration

-

Suitable for indoor or outdoor use

-

Built with durable aluminum + stainless steel housing

Features

- 360-degree rotating nozzles for dynamic, captivating spark effects.

- Adjustable effect height up to 22.96ft (upward, downward, or rotating) for versatile displays.

- Adjustable rotation speed, direction, and angle for customized effects, including rotating, waving, or fixed-direction firing.

- Simulates molten iron flower and fireworks wheel effects when combined with multiple units.

- Rainproof 304 stainless steel housing for reliable indoor and outdoor use.

- Auto dynamic control system with multi-sensor feedback for safe, dependable operation.

- Hopper capacity of 550 grams with a 50 grams per minute consumption rate for consistent performance.

- DMX control with 6 channels for precise integration into professional lighting and stage setups.

- 320x240mm color LCD screen for real-time monitoring and easy operation.

- Neutrik PowerCON TRUE1 and IP65-rated 3-Pin/5-Pin XLR connectors for secure, professional connections.

- Includes mounting hardware (eagle hook plates, washers, and screws) for flexible installation.

Specifications

General

- Model: BT83

- Dimensions: 12.20 x 12.08 x 11.22 inches

- Net Weight: 35.20 lbs

- Voltage: 100-120V, 50/60Hz

- Power Rating: 500W

- Housing Material: 304 Stainless Steel

- Internal Bracket Material: Stainless Steel

- Housing Color: Black

- Effect Direction: 360-Degree Circular

- Hopper Capacity: 550 grams

- Effect Height:

- HC8200 Medium: Not Available

- HC8200 Large: 13.12ft (Upward), 19.68ft to 22.96ft (Downward), 16.40ft to 19.68ft (Rotating)

- Adjustable Height via DMX: Yes

- HC8200 Consumption Rate: 50 grams per minute

- Screen Type: 320x240mm color LCD Screen

- Armed Indicator: Yes

- Power Connections: Neutrik PowerCON TRUE1 in/out

- XLR Connections: IP65-rated 3-Pin and 5-Pin XLR in/out

- Waterproof: Can be used in rain

- Control: DMX

- DMX Channels: 6

What’s Included

- (1) Sparkular Wheel in Black Finish

- (1) 9.84FT PowerCON TRUE1 Male to Edison Male Power Cable

- (4) Black zinc-plated 304 stainless steel spring washer, M8

- (4) Black zinc-plated 304 stainless steel flat washer, M8

- (4) Black zinc-plated 304 stainless steel hexagon socket head cylindrical cap screw, M8x20

- (2) Eagle hook mounting plate

Physical

- Shipping Dimensions: 13 x 12 x 12 inches

- Shipping Weight: 45 lbs

Specifications:

| Specification | Details |

|---|---|

| Model | sDarkular WHEEL |

| Dimensions | 19.7 in (L) × 11.8 in (W) × 23.6 in (H) |

| Shipping Weight | 45 lb |

| Power Supply | AC 100–120V / 200–240V, 50/60 Hz, 800W |

| Control Protocols | DMX, RDM |

| Rotation | 360° programmable (direction and speed adjustable) |

| Effect Type |

USER MANUAL

SPARKULAR® WHEEL

Showven Technologies Co., Ltd.

Thanks for choosing SPARKULAR® WHEEL, we wish it will sparks up your show.

Please read the following manual carefully before operating this product.

Δ Safety Instructions

\ Unauthorized repair are prohibited, it may cause serious incident.

\ SPARKULAR® WHEEL can be used in rain, please keep the device dry after use.

\ Make sure lid of feeding hopper are well covered when use SPARKULAR® WHEEL.

\ Consumable should keep away from moisture and stored in a dry sealed environment.

\ Check whether there is consumable aggregate in the output nozzle both before and after

each show, if any, please clean it up, or it will affect the firing effect, damage machine, even

cause serious incident.

\ There will be some sparks drop to ground, make sure there are no flammable objects such as

carpet on the ground within the safety radius of the machine.

\ The SPARKULAR® WHEEL power supply cable maximum allowed cascade of 6pcs (220V

version) / 3pcs (110V version), exceed connecting may result in damage or even cause fire.

\ Cover the output nozzle of SPARKULAR® WHEEL is forbidden, inspect the machine before

each show, making sure no objects or material will block the output nozzle.

\ Never touch the nozzle of SPARKULAR® WHEEL danger of getting burnt.

\ Never touch the sparks which shooting out from the nozzle.

\ Make sure no staff, audience and flammable materials stays under the SPARKULAR® WHEEL.

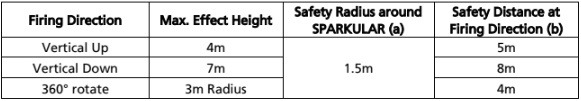

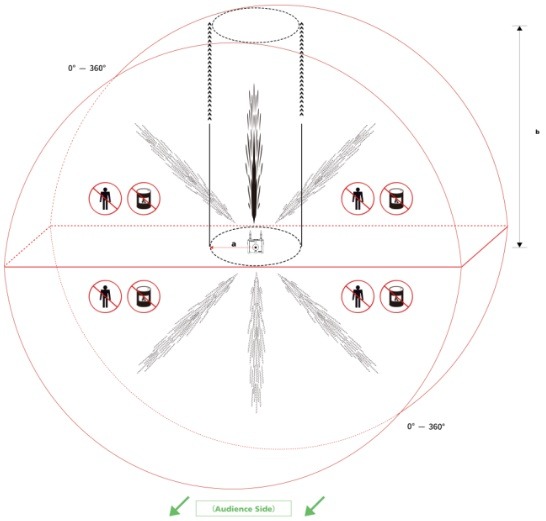

Safety Distance

\ Safety distance for SPARKULAR® WHEEL divided into two parts safety radius around machine

(a) and safety distance at firing direction (b). No person and flammable materials are allowed

to stay inside the safety isolation zone when SPARKULAR® WHEEL was armed.

\ The safety radius around machine of 1.5m.

\ For safety distance at firing direction equals to maximum firing height + 1m. SPARKULAR®

WHEEL with 360 degree rotation firing angles, when firing wave sequence the safety

isolation zone is a three-dimensional sector area.

\ When under full cycle mode, SPARKULAR® WHEEL safety isolation zone is a three-

dimensional space with a circular cross-section with radius of b, and thickness of 2a, as show

in below picture. Unauthorized persons and objects are strictly prohibited from entering.

Depending on the firing sequence / angles the safety isolation area changes accordingly.

\ In windy environment, increase the safety distance according to the wind direction and speed.

\ Sparks and consumables from the machine can lead to serious eye injury. Always wear safety

goggles when enter the safety zone.

Δ Description

SPARKULAR® WHEEL is another brand new sparks effects originally introduced by SHOWVEN®.

It is a SPARKULAR® machine with verstile output angles, the output nozzle can rotate 360

degrees and can also firing in any fixed direction. Thus it can simulate the molten iron flower

effect, if combined several units together it can also generate fireworks wheel effects. It is

versatile for both big stages and small wedding getherings.

Δ Technical Specifications

\ MODEL: BT83

\ DIMENSION: 318 307 285mm

\ WEIGHT: 15kg

\ VOLTAGE: AC 100-240V, 50/60Hz

\ WORK POWER: 500W

\ HC8200 CONSUMPTION: 50g/min

\ EFFECT HEIGHT ADJUSTBLE: YES, height level gear 1-3

\ EFFECT ANGLE ADJUSTBLE: 0°~ 360°

\ INTERFACE: 3-pin and 5-pin XLR, POWER IN/OUT

\ CONTROL: 6 DMX channels

\ WORK TEMP.: -20 C~40 C

\ CONSUMABLE AND EFFECT HEIGHT: HC8200 LARGE, vertical up 4m, vertical down 6-7m, 360°

rotate with radius of 2.5-3m.

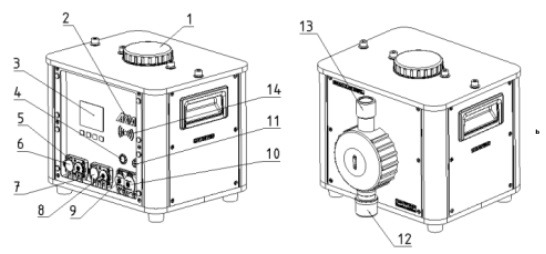

Δ Structure of SPARKULAR® WHEEL

1. Feeding Hopper Lid

2. ARM alarming light

3. Display Screen

4. Power Switch ( flash means machine is heating up, long on means temp. reached setting

temp.)

5. 5-PIN DMX IN

6. 5-PIN DMX OUT

7. 3-PIN DMX OUT

8. 3-PIN DMX IN

9. Power IN

10.Power OUT

11.Fuse

12.Blower

13.Output Nozzle

14.RFID Card Swipe Area

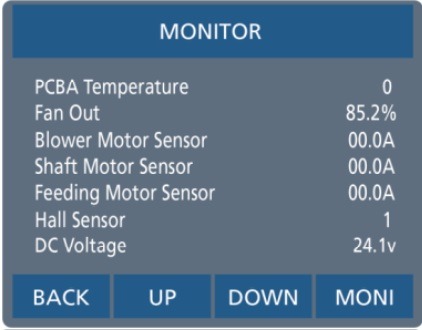

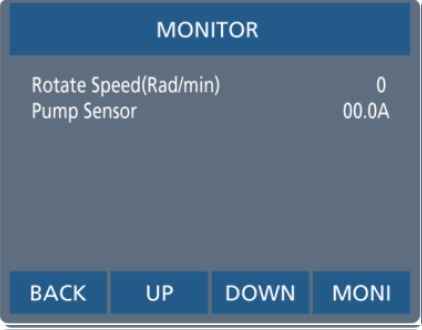

Δ Operation Panel

1. Keypad area

MENU: Press enter setting interface

UP: Parameter up

DOWN: Parameter down

MONI: Status monitoring of main part inside machine

2. Monitoring Interface

From this interface, we can check the PCB Temp, fan speed, motor status, voltage etc. to

monitoring the critical parts status of the machine.

3. RFID area

RFID card come with consumable HC8200 bags, swiping card to identify parameters and types

of granules. The RFID card is disposable, one card can only use one time. Each card can increase

single machine 20min working time, the maximum recharge time for SPARKULAR® WHEEL is

30min. SPARKULAR® WHEEL any compatible with V2.0 RFID card.

4. ARM alarming light

OFF: DMX connected

BLINK: DMX armed, ready for firing

ON: No DMX connection

NOTE: you can turn off the ARM light in ADVANCED menu by switch the ARM State to OFF

status.

Δ Display Interface

1. Main Interface:

Background color of DMX area: RED means DMX connected.

Background color of TEMP area: RED means heating chamber temp. reached setting temp.

machine is ready for firing.

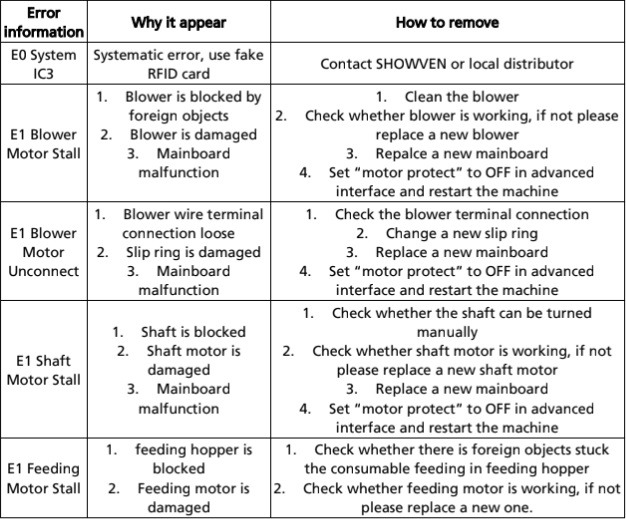

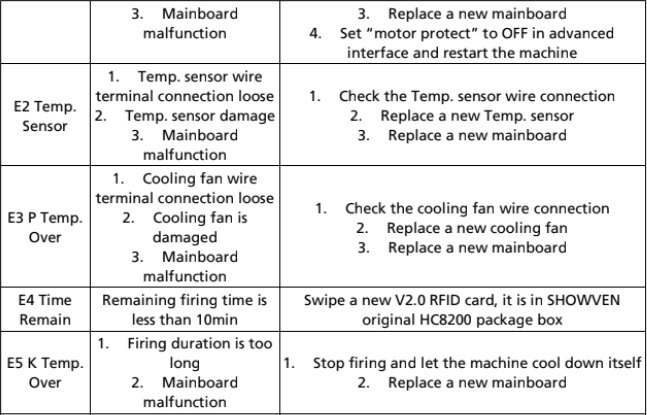

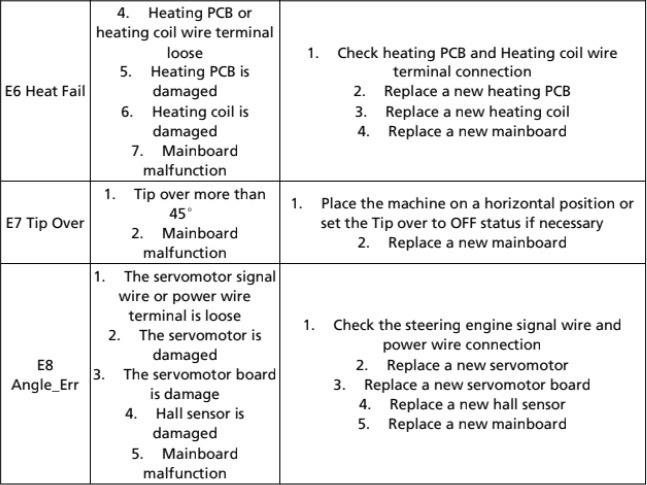

2. Error information

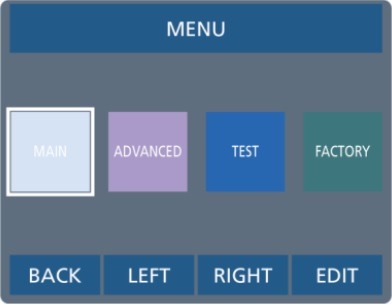

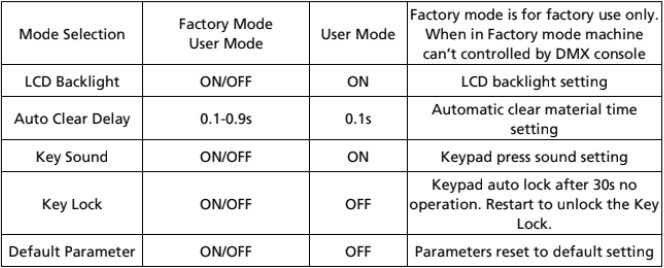

3. Set Up Menu

Press “MENU” enter setup menu, press LEFT, RIGHT to choose main menu, advanced menu, test

menu or factory menu. Press “EIDT” can entering related menu and setting up related

parameters.

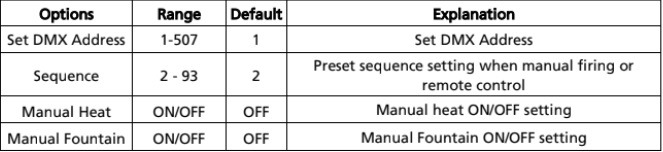

4. Main Menu

Parameters in main menu show in below table, press “UP”/ “DOWN” to change the value,

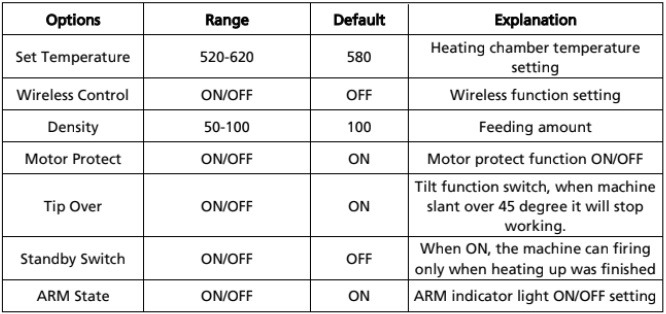

please remember to press “SAVE” to save the setting.

5. Advanced Menu

*For better performance of SPARKULAR® WHEEL, please don’t change the default value

without permission from SHOWVEN®.

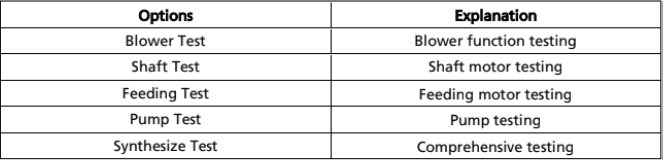

6. Test Menu

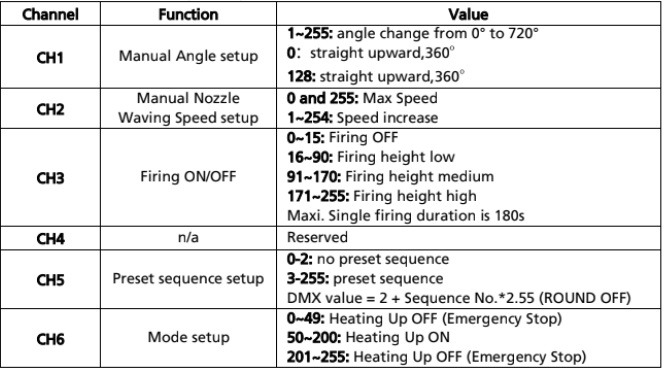

7. DMX Channel Mode

SPARKULAR® WHEEL occupies 6 operational channels.

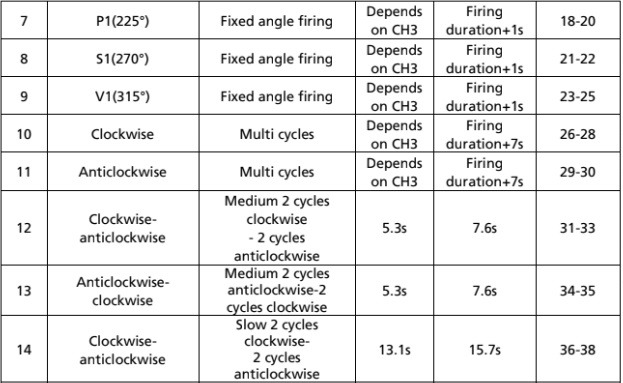

NOTE: Sequence No. 10 and No.11 output tube rotate speed can adjust throught channel 2.

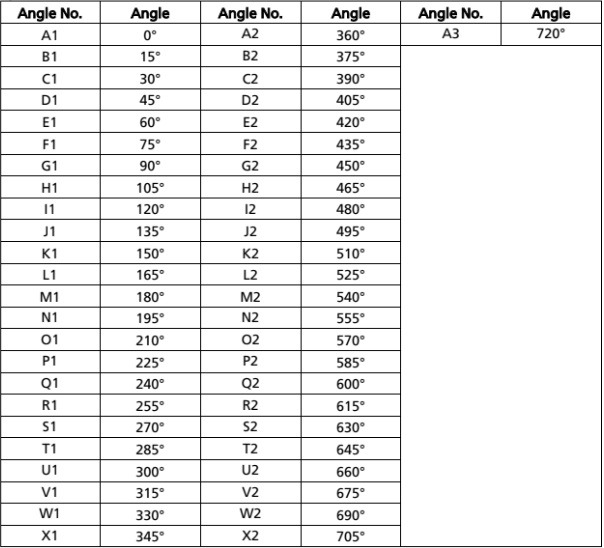

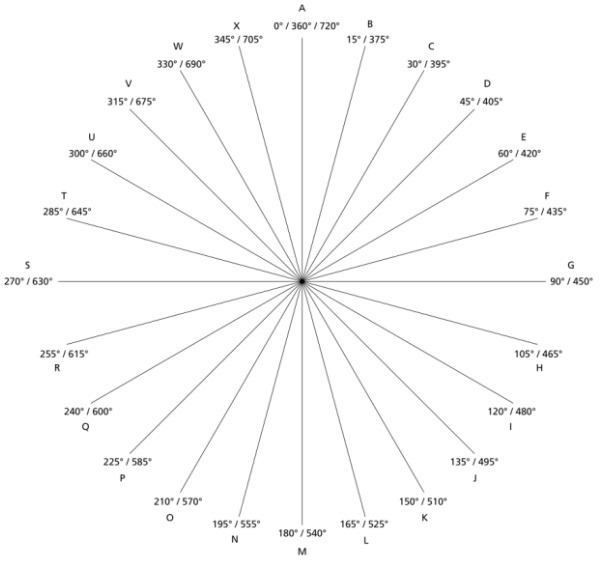

Channel 1 (CH1): Manual Angle Setup

This angle can be selected anywhere from 0 to 720 (DMX value from 1 to 255). The following

formula can be used to calculate the angle (in degrees) ![]()

SPARKUALR® WHEEL output nozzle firing angle can be 720° ( 360° * 2), from the audience

view, 0° start from vertical up 12 o’clock direction, every 15° degree a firing position, all

together 49 postions.

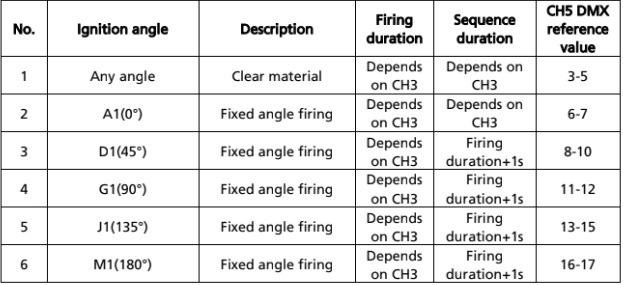

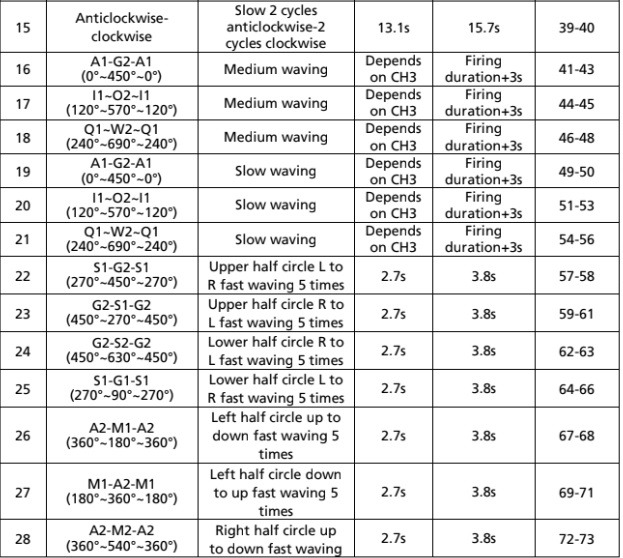

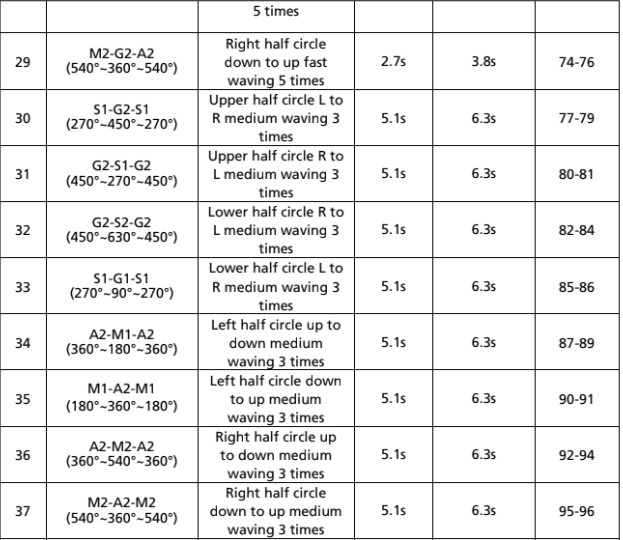

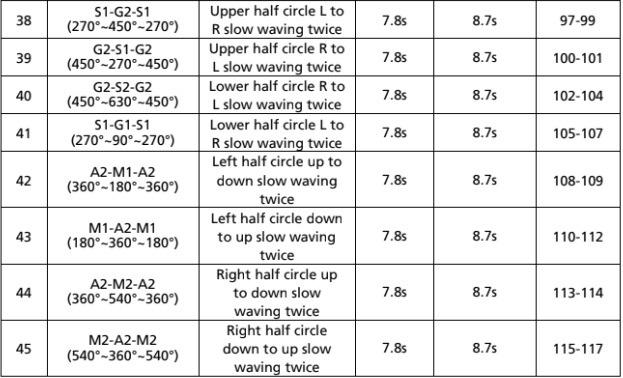

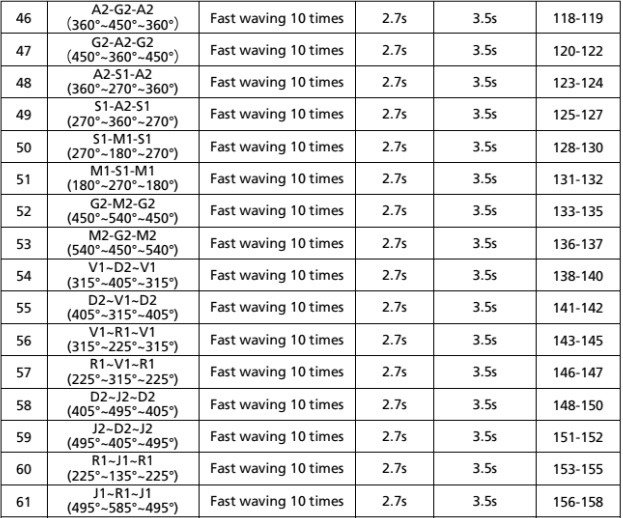

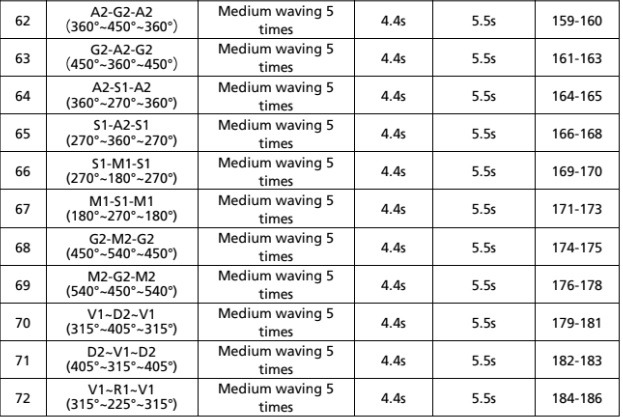

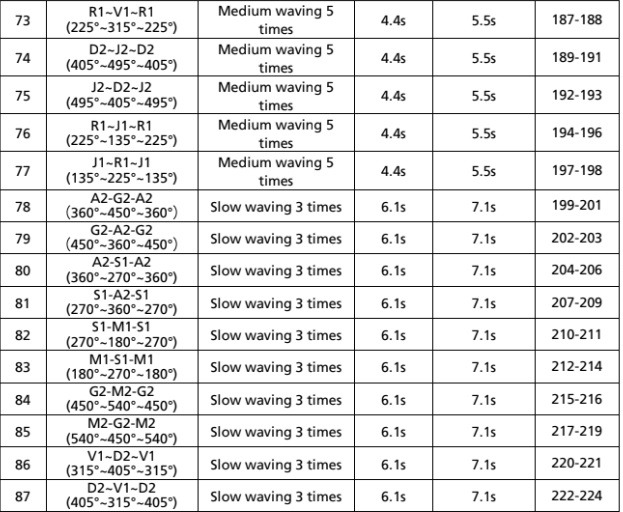

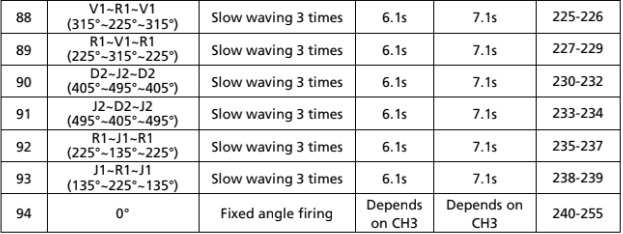

Channel 5 (CH5): Firing Sequence

SPARKULAR® WHEEL has 93 preset sequences, operator use related channel DMX value or

sequence No. to access certain sequence. Below, you can find sequence list.

DMX control example 1: firing sequence No. 42

1. Set output nozzle straight up

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 0, CH6 = 128

2. Set preset Sequence No. 42

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 108, CH6 = 128

3. Firing, put CH3 to 255 and hold for at least 1s. SPARKULAR WHEEL will finish sequence 42

automatically.

CH1 = 128, CH2 = 0, CH3 = 255, CH4 = 0, CH5 = 108, CH6 = 128

DMX control example 2: firing sequence No. 2, firing time 10s

1. Set output nozzle straight up

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 0, CH6 = 128

Set preset Sequence No. 2

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 6, CH6 = 128

2. Firing, put CH3 to 255 and hold for10s

CH1 = 128, CH2 = 0, CH3 = 255, CH4 = 0, CH5 = 6, CH6 = 128

Keep 10s.

3. Firing OFF

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 0, CH6 = 128

DMX control example 3: firing sequence No. 10

1. Set output nozzle straight up

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 0, CH6 = 128

2. Set preset Sequence No. 10

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 26, CH6 = 128

3. Firing, put CH3 to 255 and hold for 30s

CH1 = 128, CH2 = 0, CH3 = 255, CH4 = 0, CH5 = 26, CH6 = 128

Fast cycling for 30s.

4. Firing, put CH2 to 128 and hold for 30s

CH1 = 128, CH2 = 128, CH3 = 255, CH4 = 0, CH5 = 26, CH6 = 128

Medium cycling for 30s.

5. Firing OFF

CH1 = 128, CH2 = 0, CH3 = 0, CH4 = 0, CH5 = 0, CH6 = 128

8. Wireless Control

SPARKULAR WHEEL can be firing wirelessly by FXmote. When use

FXmote for remote control, please disconnect DMX cable connection,

set machine to Wireless Control to ON status in advanced menu. Select

“DEVICE” SPARKULAR on FXmore (please refer to FXmote manual),

Match machine with FXmote by Press “SET” on FXmote when machine

at Wireless Control interface.

FXmote is not standard configuration, if you need to order please

contact SHOWVEN sales.

FXmote will firing the exact sequence that you set in the main menu.

Operation Guide

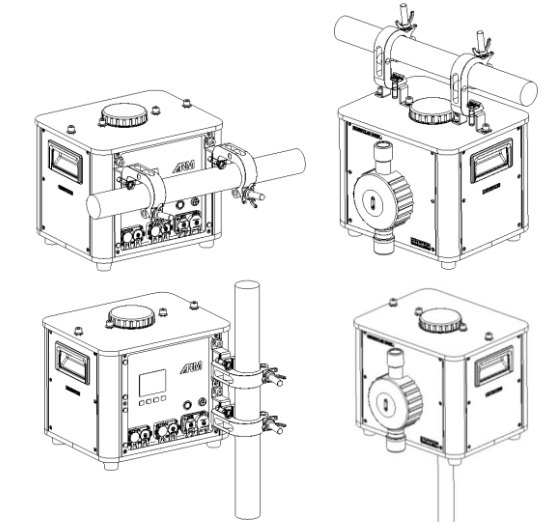

1. Install SPARKULAR®WHEEL

a) To meet different application scenario, we designed mutli installation interface for

SPARKULAR® WHEEL as show below.

b) Make sure the machine is securely installed to avoid falling, make sure to install extra safety

rope for each machine.

c) Check carefully the output nozzle of each machine, make sure the output nozzle is in good

shape and there is no powder aggregate.

2. Fill SPARKULAR® WHEEL

a) Open powder bags and fill the feeding hopper.

b) Choose correct consumable according to the hanging height and safety distance..

c) Please be noted that there may sparks or remains fall to the ground. Make sure no

flammable material on ground in the safety zone.

d) Make sure the lid of hopper is locked tight after filling.

SAFETY NOTICE: Accidentally burning of consumable HC8200 in the hopper can only use sands

to extinguish.

3. Connect Power / DMX cable

a) Connect a power cable to the POWER IN socket of SPARKULAR® WHEEL. Connect the other

end of power cable to the power source. Make sure power supply in consistent with the

rated voltage of the equipment, and the socket must well grounded.

b) If connect machine in sequence, please connect a power link cable to the POWER OUT of

previous machine, connect the other end of the power link cable to POWER IN of the next

machine.

c) The SPARKULAR® WHEEL power supply cable maximum allowed cascade is 6 units (220V

version) / 3pcs (110V version). Do not connect exceed units to a single electrical circuit.

d) Power ON all SPARKULAR® WHEEL.

e) Assign DMX address for each unit of SPARKULAR® WHEEL. If use SHOWVEN FXcommander

to control the machine please allocate a unique DMX address for each unit of machine.

If use FXmote to control SPARKULAR® WHEEL wirelessly, please set machine to wireless ON

status and match machine with FXmote. For DMX cable control please execute below

operations (f to h).

f) Connect a DMX cable to the DMX IN socket of first unit of SPARKULAR® WHEEL, connect

the male connector end of DMX cable to your DMX controller (FXcommander, FXbutton,

light console etc).

g) Connect a DMX cable to the DMX OUT of previous machine, and the other end of to the

DMX IN of next machine. Connect all devices in series in this way.

h) Plug in a DMX terminator into the DMX OUT in last unit of machine to improve signal

reliability. Signal amplifier is required for long distance (>200m) DMX signal transmission

(SHOWVEN DMX splitter 8 with bidirectional signal transmission, thus can get signal

feedback from device).

4. Activate SPARKULAR® WHEEL by swipe RFID card

a) Swipe an V2.0 RFID card. SPARKULAR® WHEEL shows time remain if read successfully.

SPARKULAR® WHEEL report E4 when remaining time is less than 10 minutes.

b) Please note each RFID card come with 200g package HC8200 can increase single machine

20min working time, the maximum recharge time for SPARKULAR® WHEEL is 30min, when

time remain reached 30min, it can’t recharge anymore RFID card.

5. Programming and Firing

a) Programming SPARKULAR® WHEEL, set the firing sequences etc.

b) Heating up, it takes few minutes, it varies according to the voltage and environment

temperature.

c) Make sure the prescribed safety zone of related firing sequences are clear.

d) Suggest to clear material for SPARKULAR® WHEEL before firing.

e) Firing. In order to prevent overheat in the heating chamber and protect machine, the

maximum continuous firing time for SPARKULAR® WHEEL is 180s.

f) The operator should always have a clear view of the device, so that he/she can stop the

show immediately when there is danger.

g) Running preset sequence No.1 to clear material for SPARKULAR® WHEEL after show, clear

material will remove the remaining particles from heating chamber.

6. Turn Off and clean up

a) Power off SPARKULAR® WHEEL, allow SPARKULAR® WHEEL to cool down.

b) Disconnect all POWER and DMX cables.

c) Empty the remaining HC8200 in hopper, and store the remaining HC8200 in a dry sealed

bottle for next time use. Never touch the output nozzle of SPARKULAR® WHEEL when

empty the hopper. DANGER OF GET BURNT!

d) Operators can use handheld vacuum cleaner to empty the feeding hopper. Do make sure

the machine was cool down when clean it. Do NOT use high-power vacuum cleaners to

avoid hot consumables being sucked into the vacuum cleaner from the heating chamber

and cause fire.

e) Clean the surroundings to remove powder residues.

Δ Maintenance

a) Empty the feeding hopper before shipment of machine.

b) Empty the feeding hopper if long time not use, for high humidity environment we suggest

to empty feeding hopper after each show.

c) Clear material both before and after the show.

Δ Warranty Instructions

\ Sincere thanks for your choosing our products, you will receive quality service from us

\ The product warranty period is one year. If there are any quality problems within 7 days after

shipping out from our factory, we can exchange a brand new same model machine for you

\ We will offer free of charge maintenance service for machines which with hardware

malfunction (except for the instrument damage caused by human factors) in warranty period.

Please don't repair machine without factory permission

Below situations NOT included in warranty service:

\ Damage caused by use other type of consumable which is not originally from SHOWVEN®.

\ Damage caused by improper transportation, usage, management, and maintenance, or

damage caused by human factors;

\ Disassemble, modify or repair products without permission;

\ Damage caused by external reasons (lightning strike, power supply etc.)

\ Damage caused by improper installation or use;

For product damage not included in warranty range, we can provide paid service.

Invoice is necessary when applying for maintenance service from SHOWVEN®